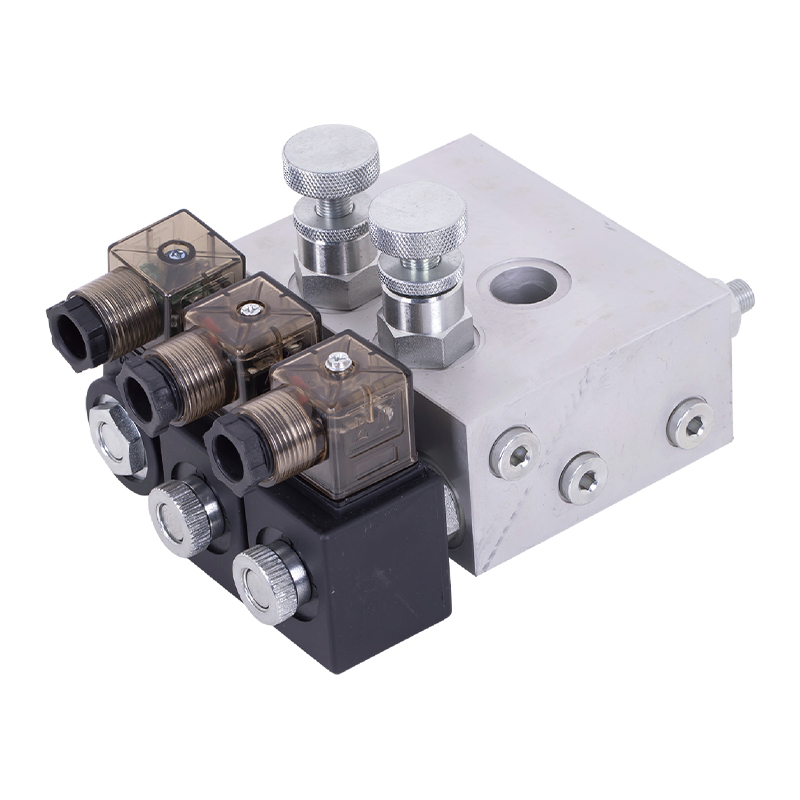

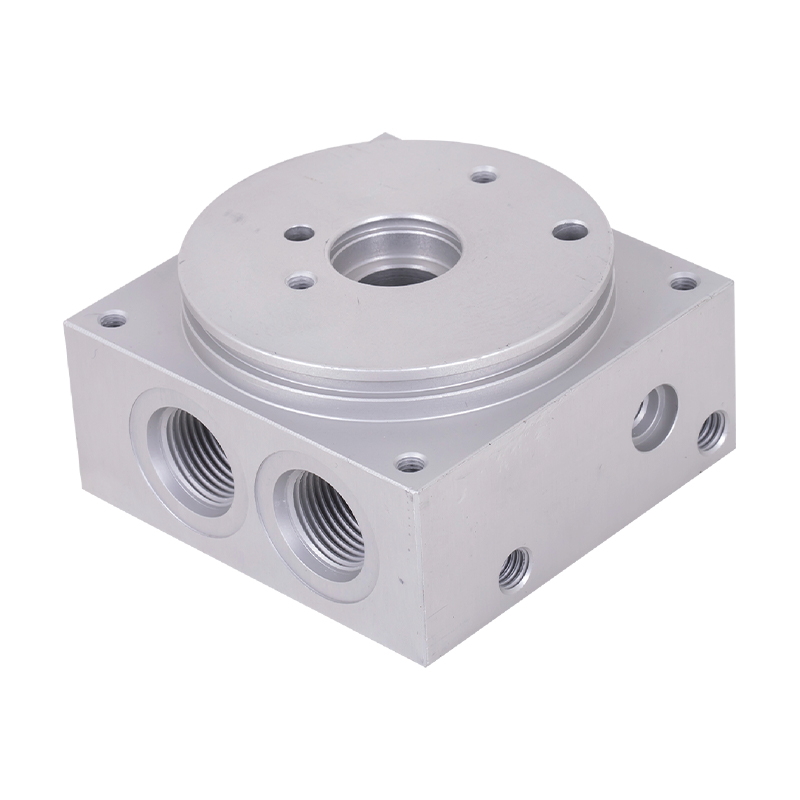

This hydraulic power unit of full electric stacker is specially designed for full electric stacker. It is integrated by a high-pressure gear pump, a DC brush motor central valve block, a cartridge valve, and an oil tank. The rise and fall are controlled by motor and solenoid valve, with optional motor power from 2.2 kW-4kW, single speed, double speed, and proportional speed regulation. There are iron and plastic fuel tanks to choose from.

MAIN FEATURES INCLUDE

- Electric control: The hydraulic power unit of full electric stacker is controlled by a motor and a solenoid valve, which can accurately adjust the lifting and lowering action of the stacker. The rising and lowering functions controlled by the solenoid valve make the stacker operation more flexible and smooth.

- Multiple motor power options: The motor power can be selected from 2.2kW to 4kW. Users can choose the appropriate motor power according to different load requirements to ensure the efficient operation of the system under various working conditions.

- Flexible descent speed selection: The hydraulic power unit of full electric stacker provides three descent modes: single speed, dual speed and proportional speed regulation. Users can choose the most suitable descent speed according to work needs to ensure the stability and safety of the stacker in different working scenarios.

- Tank material selection: The hydraulic unit provides two options: iron tank and plastic tank. Iron tanks are suitable for long-term high-load use, ensuring better durability; while plastic tanks are lighter and suitable for application environments with strict requirements on equipment weight.

- Cartridge hydraulic valve design: The system adopts a cartridge valve design, which can improve fluid control accuracy and response speed, making the hydraulic system of the stacker more efficient and reliable.

- Motor and solenoid valve control: The combination of DC carbon brush motor and solenoid valve makes the stacker operation smoother, the lifting action more precise, and the system starts quickly, reducing energy waste and improving overall operating efficiency.

This hydraulic power unit is suitable for all-electric stackers and can provide them with stable hydraulic support, especially in working environments that require fast lifting and flexible speed regulation, which can effectively improve work efficiency. The combination of cartridge hydraulic valve and motor control system ensures the precise control and efficient operation of the hydraulic system, adapting to different types of stacking operations.

SPECIAL NOTES

The power unit is an S3 working system and can not operate continuously. It starts in 10 seconds and stops in 90 seconds.

Before installation, ensure that hydraulic components such as the oil cylinder, oil pipe, and joint are free of impurities.

The viscosity of hydraulic oil shall be 15 - 68st. No. 46 anti-wear hydraulic oil is recommended in summer, and No. 32 low-temperature hydraulic oil is recommended in winter.

After starting the operating system for the first time, check whether the oil in the oil tank is sufficient, generally 2/3 of the oil tank.

After the system is used for the first 100 hours, the hydraulic oil shall be replaced, and then the hydraulic oil shall be replaced every 3000 hours.

SCHEMATIC DIAGRAM

SPECIFICATIONS

(Hydraulic power unit of full electric stacker 1)

| Model | Volt | Power | Speed | Displacement | Pressure | Tank | Solenoid Valve Voltage |

| PNC-2.2-D24-1/2.7-20-5/L-Y2 | 24VDC | 2.2KW | 260ORPM | 2.7CC/REV | 20MPA | 5L | 24V |

| PNC-3-D24-1/3.2-20-10/L-Y4 | 3KW | 3.2CC/REV | 10L | ||||

| PNC-4-D24-1/3.5-20-10/L-Y5 | 4KW | 350ORPM | 3.5CC/REV |

(Hydraulic power unit of full electric stacker 2)

| Model | Volt | Power | Speed | Displacement | Pressure | Tank | Solenoid Valve Voltage |

| PNC-2.2-D24-1/2.7-20-5/L-Y2 | 24VDC/48VDC | 2.2KW | 2600RPM | 2.7CC/REV | 20MPA | 5L | 24V |

| PNC-3-D48-1/3.2-20-10/L-Y4 | 3KW | 3.2CC/REV | 10L | ||||

| PNC-4-D24-1/3.5-20-10/L-Y5 | 4KW | 3500RPM | 3.5CC/REV |

Note: if you need system parameters such as pump, pressure, and motor power with different flow, please contact our salesman.

English

English 中文简体

中文简体 русский

русский