In CNC machine tool applications, hydraulic clamping power unit of machine tools play a vital role. They provide precise and reliable clamping force through hydraulic systems to ensure that workpieces are stably fixed during high-speed processing.

Question 1: What is the basic definition and core function of hydraulic clamping power unit of machine tools?

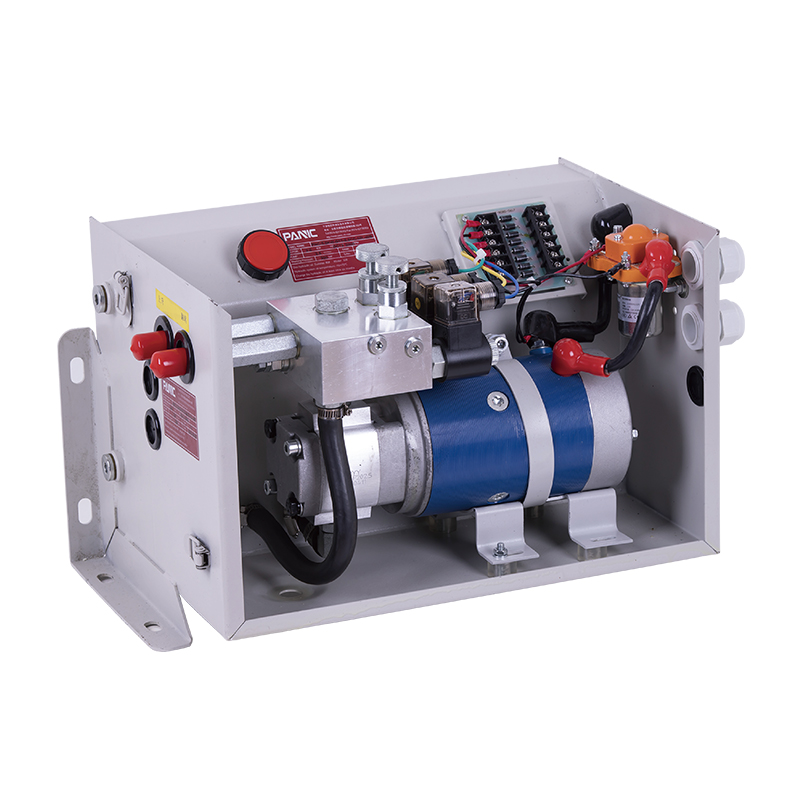

The hydraulic clamping power unit of machine tool is a key subsystem in CNC machine tools, which is responsible for generating and controlling hydraulic pressure to drive the clamping device to apply uniform force to the workpiece.

Its core functions include achieving fast and high-precision clamping actions to ensure that the workpiece remains absolutely fixed during cutting, drilling or milling to prevent displacement or vibration.

The system is usually integrated into the machine tool hydraulic circuit, involving components such as pressure sources, control valves and actuators, emphasizing stability and reliability.

Combined with the practice of Ningbo Panic Hydraulic Technology Co., Ltd., the company strengthens this function in customized solutions, improves the overall durability of the unit through high-quality materials, and meets the needs of harsh industrial environments.

Question 2: What hydraulic principles are the working mechanism of this power unit based on?

The working mechanism is based on Pascal's law and uses the principle of pressure transmission of incompressible fluids: the hydraulic pump draws fluid from the tank, generates high pressure through boosting, and then distributes it to the actuator (such as a hydraulic cylinder) through a control valve.

The actuator converts hydraulic energy into mechanical force to drive the clamping mechanism to complete the action; the system also includes a pressure regulator and a safety valve to ensure that the pressure is stable within the set range.

Throughout the process, the feedback mechanism monitors the clamping force in real time and realizes closed-loop control to adapt to the changes in different processing loads.

Ningbo Panic Hydraulic Technology Co., Ltd. uses advanced materials to optimize fluid dynamics and reduce energy losses when designing such units, thereby improving efficiency and reducing maintenance frequency.

Question 3: What are the main advantages of hydraulic clamping power unit of machine tools compared to other clamping methods?

The precision advantage is reflected in the high sensitivity of force control. The hydraulic system can achieve micron-level adjustment to ensure uniform distribution of clamping force and avoid deformation or damage to the workpiece.

Outstanding reliability and durability: the unit operates stably under high pressure, with low vibration and low noise, suitable for long-term continuous processing; material selection such as wear-resistant alloys and sealing components prolongs the service life.

In terms of economy, the unit reduces energy consumption through efficient energy conversion, and with low-friction design, reduces component wear and achieves long-term cost savings.

The solution provided by Ningbo Panic Hydraulic Technology Co., Ltd. emphasizes these advantages, using customized design and cost-effective strategies to reduce downtime in complex applications and improve the overall output of machine tools.

Question 4: How does material selection affect the performance and life of hydraulic power units?

The material directly determines the sealing and corrosion resistance of the unit: key components such as pump bodies, valve cores and pipes are made of high-strength stainless steel or alloy steel to prevent fluid leakage and chemical erosion, ensuring long-term airtightness of the system.

The durability improvement comes from the heat treatment and surface treatment of the material: for example, hardened coatings reduce friction and wear and extend the service life of moving parts; high-performance sealing materials (such as polytetrafluoroethylene) resist high-pressure shock.

In terms of performance optimization, lightweight alloy materials reduce the weight of the unit and facilitate integration, while maintaining structural rigidity to adapt to the dynamic load of high-speed machining.

Ningbo Panic Hydraulic Technology Co., Ltd. uses world-class materials in unit manufacturing to enhance this effect. Through strict material selection standards, it ensures that the clamping power unit maintains efficient operation under extreme conditions and reduces the failure rate.

Question 5: How to achieve high cost-effectiveness and low maintenance requirements for hydraulic clamping power unit of machine tools?

Cost-effectiveness comes from optimized design: the system simplifies the circuit structure, reduces redundant components, and reduces manufacturing costs through modular layout; at the same time, intelligent control strategies (such as variable frequency pumps) match load requirements and reduce energy waste.

Low maintenance is achieved by preventive design: self-lubricating bearings and maintenance-free seals extend service intervals; easily accessible maintenance points facilitate rapid maintenance and avoid downtime losses.

Long-term economic efficiency is reflected in the total cost of ownership calculation: the initial investment is quickly paid back by reducing energy consumption and spare parts replacement, and the overall expenditure during the unit life cycle is better than mechanical or pneumatic clamping solutions.

Ningbo Panic Hydraulic Technology Co., Ltd. highlights this feature in hydraulic solutions, emphasizes high cost-effectiveness and low maintenance costs when providing customized units, and uses high-quality materials to predict potential problems to ensure that users gain sustainable operational advantages.

Question 6: What is the role and importance of customization in the application of hydraulic clamping power unit of machine tools?

Customization solves machine tool compatibility issues: Different machining centers require specific clamping force ranges, installation dimensions and interface protocols. The unit can adjust pressure output, flow curve and external dimensions to match unique needs.

The importance lies in improving system integration: customized design optimizes space utilization and avoids conflicts with other subsystems of the machine tool; at the same time, customized units strengthen pressure control and improve processing safety based on material properties (such as workpiece hardness).

Significant efficiency gains: Through personalized configuration, the unit shortens the clamping/unclamping cycle time, increases machine tool throughput, and supports automation upgrades, such as seamless communication with CNC systems.

Ningbo Panic Hydraulic Technology Co., Ltd. focuses on such customized hydraulic solutions, combines its material advantages, and provides adaptation solutions for various machine tools to ensure that the clamping power unit can achieve maximum performance in diverse applications.

English

English 中文简体

中文简体 русский

русский