In the field of industrial automation, telescopic belt power units are widely used in scenarios such as material transportation and production line expansion as a core transmission component. Ningbo Panic Hydraulic Technology Co., Ltd. relies on its rigorous quality management system to ensure that every telescopic belt power unit product meets high standards, which is specifically reflected in the multi-level inspection process in mass production.

What is the basic definition of a telescopic belt power unit?

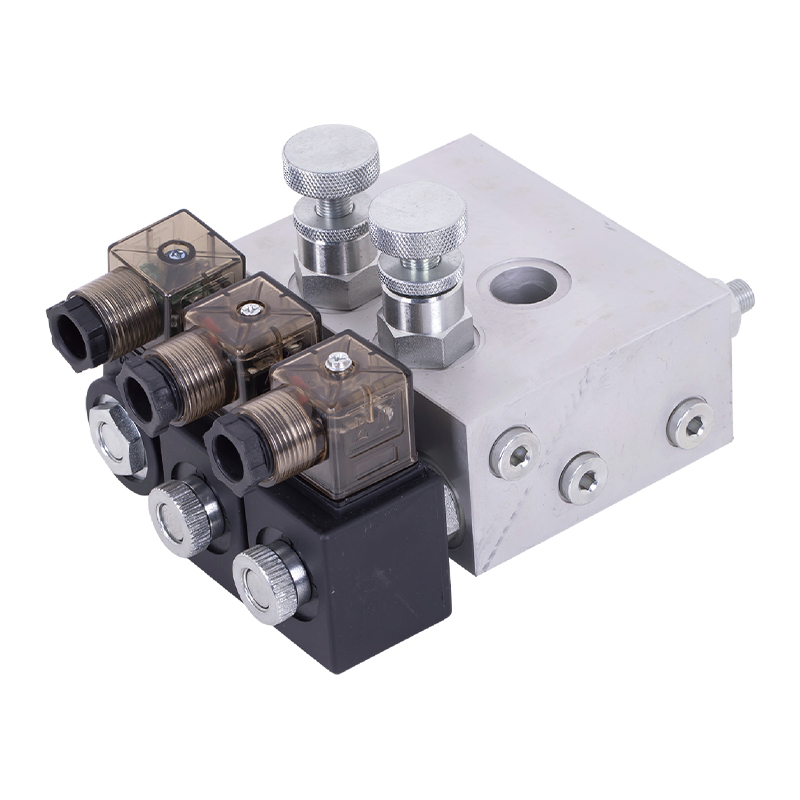

A telescopic belt power unit is an adjustable-length belt drive system that uses a mechanical structure to extend and retract the belt to meet the needs of different working distances. Its core components include a drive motor, pulley, tensioner and telescopic mechanism, which together form an efficient power transmission unit. Ningbo Panic Hydraulic Technology Co., Ltd. uses standardized processes from raw material procurement to final assembly when producing such units to ensure the overall rigidity and durability of the unit. The first inspection after each process verifies the initial parameters to prevent early defect accumulation.

How does the telescopic belt power unit work?

The working principle of the unit is based on the belt drive principle combined with the linear motion of the telescopic mechanism. The drive motor transmits torque through the pulley to drive the belt to rotate; the telescopic mechanism adjusts the belt length hydraulically or mechanically to dynamically adapt to the working environment. Ningbo Panic Hydraulic Technology Co., Ltd. has strengthened the reliability of this principle in manufacturing. For example, during the assembly of the power unit, irregular inspections are carried out to monitor the synchronization of the telescopic mechanism and the balance of belt tension. This inspection method directly improves the response speed and energy efficiency of the unit.

What are the main application scenarios of telescopic belt power units?

Telescopic belt power units are widely used in logistics sorting systems, warehouse automation equipment and industrial production lines, and are particularly suitable for occasions where frequent adjustment of the conveying distance is required. Its advantages are reducing the equipment footprint, improving space utilization, and supporting modular design. For these applications, Ningbo Panic Hydraulic Technology Co., Ltd. implements full inspections at the finished product stage and performs performance tests according to customer requirements and international standards such as ISO 9001, including load-bearing capacity and telescopic accuracy verification. This ensures the stable performance of the unit under different working conditions.

What are the core advantages of telescopic belt power units compared to traditional transmission systems?

The core advantages of telescopic belt power units include high flexibility, low maintenance costs and excellent energy saving. Its telescopic design allows dynamic adaptation to changes and reduces downtime; at the same time, the optimization of belt materials reduces friction losses and extends service life. Ningbo Panic Hydraulic Technology Co., Ltd. strengthens these advantages through full process quality control. For example, in mass production, the first inspection and random inspection focus on the wear resistance of the belt and the thermal stability of the drive system to ensure that the unit remains efficient in long-term operation.

How does Ningbo Panic Hydraulic Technology Co., Ltd. improve the reliability of telescopic belt power units through quality management?

Ningbo Panic Hydraulic Technology Co., Ltd. incorporates the production of telescopic belt power units into a strict quality assurance system. After each process of mass manufacturing, a first inspection is performed to confirm key parameters such as belt tension and axle alignment; random inspections are carried out during production to monitor component consistency; and full inspections are carried out at the finished product stage to evaluate overall performance according to customer specifications and international standards. This multi-level inspection mechanism effectively prevents defects, ensures the durability and safety of the unit, and supports its long-term application in harsh industrial environments.

English

English 中文简体

中文简体 русский

русский