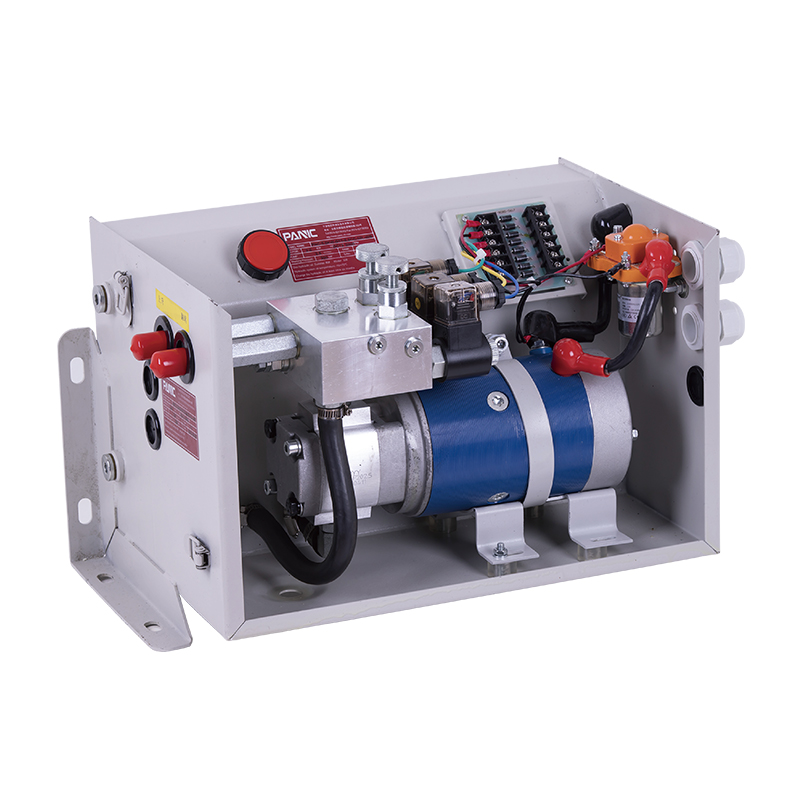

This hydraulic pump station is composed of a series of side inlet and side outlet gear pumps and 4.5 or 5-inch DC motors. It is often used as a hydraulic power source and is widely used in the hydraulic systems of various mobile equipment. The voltage can be 12-48.

MAIN FEATURES INCLUDE:

- High-efficiency gear pump: This DC motor pump station adopts a 1 series side-inlet and side-out gear pump with efficient hydraulic power transmission capability. The design of the gear pump makes the flow of hydraulic oil stable, which can ensure that the system can maintain good performance even when working under high load.

- DC motor drive: Equipped with a 4.5 or 5-inch DC motor, it has high efficiency and stability. These motors provide strong power output and can ensure long-term stable operation of the hydraulic system, suitable for a variety of working environments.

- Voltage selection: The DC motor pump station provides a variety of voltage configurations such as 12V, 24V, 36V and 48V. Users can choose the appropriate voltage version according to the needs of the equipment and power system to ensure the compatibility and efficiency of the equipment.

- Stable performance: This DC motor pump station is designed with a focus on performance stability and can provide reliable hydraulic power under various working conditions. Whether in high or low temperatures or in dusty environments, the system can ensure the smooth operation of hydraulic equipment.

- Widely used: This DC motor pump station is suitable for a variety of mobile equipment hydraulic systems, such as construction machinery, agricultural equipment, transport vehicles, etc. Whether it is small or medium-sized equipment, it can provide sufficient power support to help improve work efficiency.

This DC motor pump station has become an important power source for hydraulic systems of various mobile equipment with its efficient and stable performance. Whether it is daily use or heavy-load operation, it can provide continuous and reliable hydraulic support, and is widely used in various types of construction and agricultural machinery, logistics equipment, etc.

SPECIAL NOTES

The power unit is an S3 working system and can not operate continuously. It starts in 10 seconds and stops in 90 seconds.

Before installation, ensure that hydraulic components such as the oil cylinder, oil pipe, and joint are free of impurities.

The viscosity of hydraulic oil shall be 15- 68 st. No.46 anti-wear hydraulic oil is recommended in summer, and No.32 low temperature hydraulic oil is recommended in winter.

After starting the operating system for the first time, check whether the oil in the oil tank is sufficient, generally 2 / 3 of the oil tank.

After the system is used for the first 100 hours, the hydraulic oil shall be replaced, and then the hydraulic oil shall be replaced every 3000 hours.

SCHEMATIC DIAGRAM

SPECIFICATIONS

| Model | Volt | Power | Speed | Displacemet | Pressure | Tank | Solenoid Vavle Volt |

| PNC-1.6-D12-1/1.6-20-YO | 12VDC | 1.6KW | 2800RPM | 1.6CC/REV | 20MPA | NULL | 12VDC |

| PNC-2.2-D24-1/2.7-20-YO | 24VDC | 2.2KW | 2600RPM | 2.5CC/REV | 24VDC | ||

| PNC-3.0-D48-1/3.2-20-YO | 3.0KW | 3.2CC/REV | 48VDC |

Note: if you need system parameters such as pump, pressure, and motor power with different flow, please contact our salesman.

English

English 中文简体

中文简体 русский

русский