In the industrial and construction fields, storage flush doors are widely used in wastewater treatment, storage facilities and other environments. The reliability and efficiency of their core drive components, the power unit, are crucial. As the core of the hydraulic system, the power unit is responsible for providing stable power output to control the opening and closing of the flush door. Ningbo Panic Hydraulic Technology Co., Ltd. (Panic) has injected lasting vitality into this type of unit through supply chain integration, technological innovation and quality control with its deep cultivation in the field of hydraulic technology.

Question 1: What is the basic definition of the power unit of storage flushing door and its role in the system?

Answer:

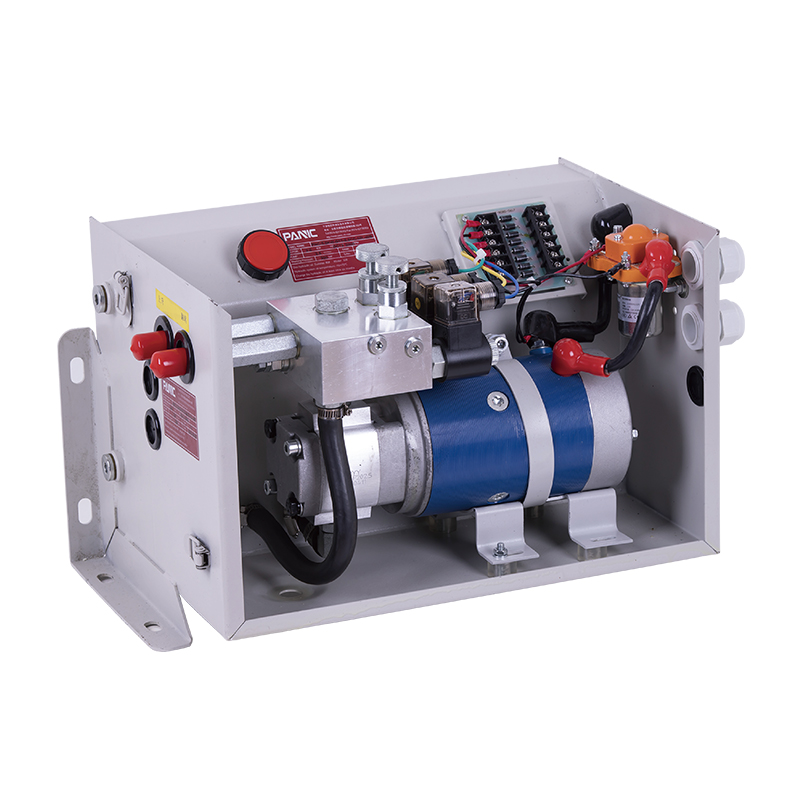

The power unit is the core component of the hydraulic drive system, designed specifically for storage flush doors. It is mainly used to convert electrical energy or mechanical energy into hydraulic energy to control the rapid opening and closing of the door body.

In flush door applications, the unit ensures a stable supply of high-pressure fluids (such as hydraulic oil) to cope with frequent operations and high-pressure environments, avoiding the risk of leakage or failure.

Through the perfect integration of the upstream supply chain, Panic ensures a reliable source of core components of the unit (such as pumps, valves and sensors), which directly improves its response accuracy and life under complex working conditions.

Question 2: What are the key components of the power unit and their functional highlights?

Answer:

As an energy conversion hub, the hydraulic pump converts mechanical power into fluid pressure to ensure the instantaneous high-pressure output required for flushing door operation.

The control valve module is responsible for regulating the flow direction and flow of the fluid to achieve precise positioning and speed control of the door and reduce operational delays or jitters.

The oil storage tank and filtration system maintain the cleanliness and temperature stability of the hydraulic oil to prevent system wear or failure caused by the accumulation of pollutants.

Panic insists on independent innovation of core technologies. For example, it uses intelligent algorithms in valve body design to optimize response time and energy efficiency, which stems from its continuous investment in miniaturization and intelligent R&D strategies.

Question 3: How does the operating principle of the power unit adapt to harsh environments, such as high-pressure and high-frequency operation scenarios?

Answer:

The operation is based on Pascal's law. The uniform transmission of fluid pressure ensures the consistency of power output and keeps the door body moving smoothly even under high-pressure shocks.

The system design integrates a pressure compensation mechanism to automatically adjust the flow to cope with load changes and avoid overload or idling problems.

Environmental adaptability requires the unit to be airtight and corrosion-resistant, and material selection needs to consider factors such as temperature fluctuations and chemical corrosion.

Panic implements a strict quality system, including full life cycle testing and simulation, to ensure that the unit demonstrates long-term reliability in extremely demanding markets (such as industrial wastewater treatment plants), thanks to its high standards for screening supply chain components.

Question 4: How does Ningbo Panic Hydraulic Technology Co., Ltd. enhance the performance advantages of power units through technological innovation?

Answer:

Implement a miniaturization strategy for hydraulic units to reduce unit size and weight while maintaining power density, making it easier to install and maintain in space-constrained flushing door systems.

Intelligent R&D introduces embedded control systems to achieve remote monitoring and fault diagnosis, improve automation levels and reduce the need for manual intervention.

Independent innovation of core technologies focuses on energy-saving optimization, such as the use of variable pump design to dynamically adjust energy consumption to match operating requirements, greatly extending the service life of equipment.

These strategies make Panic's products stand out in the highly competitive hydraulic field, and ensure the leading position of technological iteration through continuous investment.

Question 5: What are the key considerations for maintenance and reliability assurance of power units?

Answer:

Regular maintenance focuses on hydraulic oil replacement and filter cleaning to prevent system blockage and performance degradation. It is recommended to follow the maintenance cycle provided by the manufacturer.

Reliability design emphasizes redundant mechanisms, such as spare pump sets or pressure relief devices, to ensure that the system can still operate safely in the event of partial failure.

The overall life of the unit is subject to material durability and manufacturing processes, and long-term stability must be verified through accelerated aging tests.

Panic's strict quality system covers the entire process control from raw material storage to finished product delivery. Combined with supply chain integration, its power unit exhibits excellent fatigue resistance and low failure rate in harsh environments, which has become the cornerstone of its market competitive advantage.

The expertise of the power unit of storage flushing door involves multidisciplinary intersections such as fluid mechanics, material science and control systems. Its efficiency and reliability directly determine the overall performance of the flush door. Ningbo Panic Hydraulic Technology Co., Ltd. transforms these theoretical knowledge into actual product strength through supply chain integration, innovative research and development, and quality assurance, allowing its hydraulic units to continue to lead the market. This principle-based practical approach is worthy of in-depth reference by the industry.

English

English 中文简体

中文简体 русский

русский