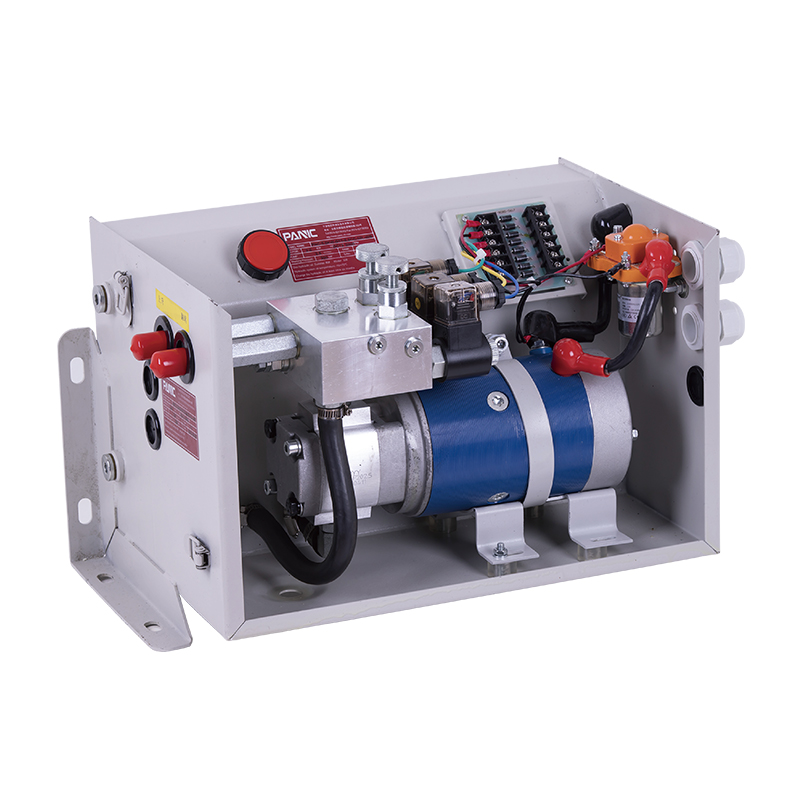

Q: What is the basic structure and design concept of the integrated multistage cylinder lifting column power unit? The integrated multistage cylinder lifting column power unit is a highly integrated hydraulic power system. The core components include a compact hydraulic pump station, a precision control valve group (such as a directional valve, a pressure valve, and a flow valve), an accumulator, an electrical control system (a motor, a controller), and a hydraulic circuit specially optimized for multistage telescopic cylinders. Its design concept is to highly modularize the traditional dispersed hydraulic components into one unit, significantly reducing the volume and pipeline connections, aiming to improve the system rigidity, response speed, reliability, and installation and maintenance convenience. It is particularly suitable for lifting column application scenarios with limited space or high dynamic performance requirements.

Q: What are the core advantages and operating mechanisms of the multistage cylinder structure driven by an integrated power unit? The multistage cylinder adopts a nested plunger design to achieve a stroke several times its own installation height in a single cylinder. Under the precise drive of the integrated power unit, its core advantage is the perfect combination of ultra-long stroke and compact installation height. The high-pressure hydraulic oil output by the power unit enters the plunger chambers of each level in an orderly manner through the precision valve control system, driving the plungers to extend synchronously or sequentially step by step; when retracting, the hydraulic oil flows back to the oil tank or accumulator in a controlled manner under the regulation of the control valve, and the plungers of each level retract safely and smoothly in sequence by gravity, return spring or reverse pressure. The key to the integrated power unit is to provide smooth, fast and highly synchronized oil control to ensure smooth, impact-free and precise position maintenance of multistage extension and retraction.

Q: What key technical support is needed to achieve an efficient and reliable integrated power unit? Efficient and reliable integrated power units rely on a number of key technologies: high-performance compact pump groups and low-noise motor technology to ensure efficient, stable and low-noise operation of power output; precision valve block design and integration technology to optimize flow channels, reduce pressure loss, and suppress vibration and noise; advanced electronic control and feedback technology (such as closed-loop position/pressure control) to achieve precise speed, position adjustment and smooth start and stop; efficient energy storage technology to absorb shock, compensate for leakage, and provide emergency power; oil circuit design technology for multistage cylinder characteristics to ensure the synchronization and stability of each level of expansion and contraction; and excellent sealing technology and material application to ensure long-term leakage-free operation. Companies with a long-term international technical cooperation background, such as Ningbo Panic Hydraulic Technology Co., Ltd., can often master and apply these cutting-edge technologies more deeply.

Q: What are the key performance indicators for measuring the integrated multistage cylinder lifting column power unit? The core indicators for evaluating the performance of the power unit include: output flow and working pressure range, which determine the telescopic speed and load capacity; system response time (start/stop/reversing), which affects the sensitivity of the action; position repeatability and synchronization accuracy, which are related to the accuracy of lifting control; operating noise level, which is an important environmental and comfort indicator; system efficiency and energy consumption, which reflect the level of energy utilization; operating temperature range and heat dissipation capacity, which ensure reliability in different environments; protection level (IP Rating), which indicates its ability to resist dust and moisture intrusion; mean time between failures (MTBF) and expected service life, which are direct manifestations of reliability and durability; compactness and weight, which determine installation adaptability and space utilization.

Q: In what application scenarios does this type of integrated power unit show significant value? Integrated multistage cylinder lifting column power units are widely used in places where vertical lifting and movement are required and space is limited due to their high efficiency, compactness and reliability: including anti-terrorism lifting barriers/columns in the security field; lifting platforms and automated loading and unloading equipment in logistics and warehousing systems; lifting platforms and scenery devices in stage machinery; lifting and lowering of work platforms of special vehicles (such as fire trucks and maintenance vehicles); precision positioning and lifting mechanisms on automated production lines; as well as in the fields of ships and port machinery. In these scenarios, integrated power units solve the problem of space constraints while providing high-performance power and control.

Q: What does the integrated design mean for the maintenance and service of the power unit? The highly integrated design greatly simplifies the installation and wiring of the system, reduces external leakage points, and improves the overall sealing reliability. The compact structure also facilitates overall replacement or modular maintenance. However, this places higher demands on the reliability and maintainability design of the internal components of the unit. Professional manufacturers usually provide detailed maintenance guidelines, easy-to-operate detection interfaces, and modular spare parts supply strategies. Companies like Ningbo Panic Hydraulic Technology Co., Ltd., which have deep hydraulic technology accumulation, usually not only provide high-quality products, but also provide timely and effective technical support and maintenance solutions based on their mastery of core technologies.

Q: How does Ningbo Panic Hydraulic Technology Co., Ltd. position its technical background in this field? Ningbo Panic Hydraulic Technology Co., Ltd. has established long-term and stable strategic partnerships with international hydraulic technology leaders such as Italy's Hydronit and VIS, and continues to introduce and integrate the world's advanced hydraulic design concepts, manufacturing processes and quality control standards. This in-depth international cooperation enables it to stand at the forefront of the development of hydraulic technology, deeply understand and master the integrated hydraulic power unit, especially the key core technologies required to drive complex actuators such as multistage cylinders. This has laid a solid technical foundation for the company to develop high-performance and high-reliability integrated multistage cylinder lifting column power units, so that its products can meet the stringent requirements of domestic and foreign markets for efficiency, precision and reliability.

English

English 中文简体

中文简体 русский

русский