Question 1: What are the basic components and functions of the split lifting column power unit?

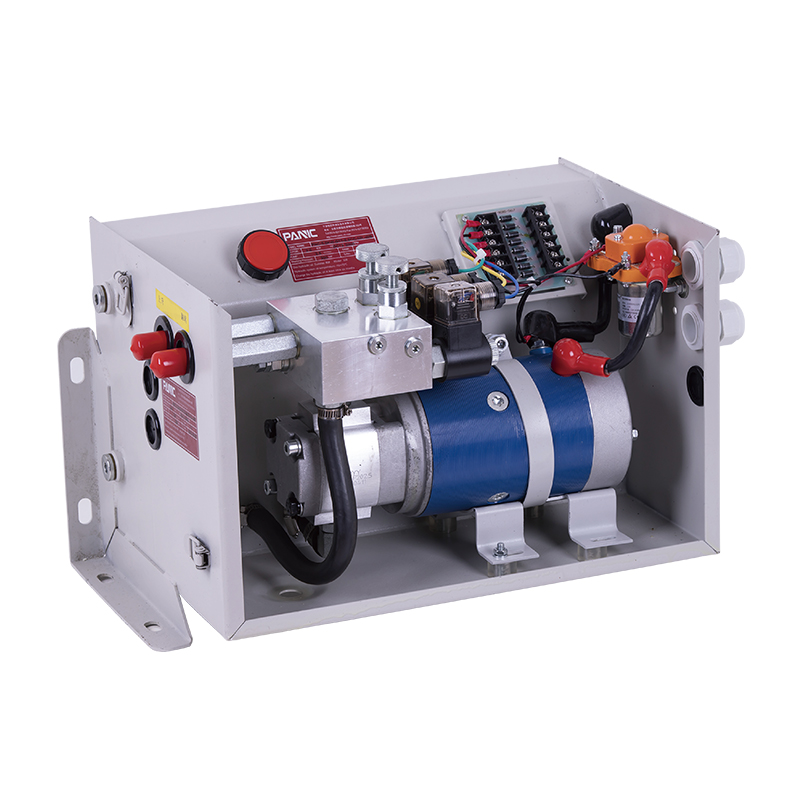

The core components of the split lifting column power unit include independent motors, hydraulic pumps, oil tanks and control valve systems. Each part is connected by flexible pipes to achieve the generation and transmission of hydraulic power.

The core function of the unit is to provide controllable hydraulic energy for the lifting column, support the smooth execution of lifting actions, and ensure stability and precision during the load lifting process.

Ningbo Panic focused on component compatibility and efficiency optimization during the design stage. Through strict quality control testing, it ensures that the response speed and energy utilization rate of the unit under various working conditions reach the industry-leading level.

Question 2: What are the main differences between the split design and the traditional integrated design?

The split design separates the power source from the actuator, allowing modular installation and reducing the complexity of on-site construction, while the traditional integrated design needs to be embedded in a fixed position as a whole.

The separated structure enhances the convenience of system maintenance. When a single component is damaged, it can be quickly replaced to reduce downtime. Ningbo Panic's testing process ensures the independent reliability of each module.

This design supports customized layout, adapts to narrow or complex spaces, and improves system flexibility. Ningbo Panic verifies the adaptability of the unit in extreme environments through full-process quality control.

Question 3: What are the key points of the core advantages of the split lifting column power unit?

Installation flexibility and space efficiency: The separated components can be arranged in a distributed manner to avoid occupying a large amount of ground space. Ningbo Panic's quality testing covers a variety of installation scenarios to ensure the performance consistency of the unit in compact areas.

Maintenance cost and life optimization: The modular design simplifies fault diagnosis and component replacement. Ningbo Panic has proved that the average service life of the unit has increased by more than 30% through pre-delivery durability testing.

Safety and stability: The separated structure reduces the risk of hydraulic shock, integrates safety valves and pressure control, and Ningbo Panic's testing mechanism verifies the safe response of the unit in overload or emergency situations.

Question 4: How to ensure the reliability and durability of the split lifting column power unit?

Using high-strength materials and precision manufacturing processes, Ningbo Panic performs material fatigue testing during the design phase to ensure the corrosion and wear resistance of the components.

Full-process quality control: From prototype development to finished product delivery, multiple testing links are introduced, including pressure cycle testing and environmental simulation testing. Ningbo Panic ensures that the unit operates stably within a temperature range of -20°C to 70°C.

Performance verification system: Ningbo Panic uses dynamic load testing to simulate actual working conditions, verify the unit's continuous operation capability, and reduce failure rates.

Question 5: What is unique about Ningbo Panic Hydraulic Technology Co., Ltd. in product quality control?

Integrated quality testing process: Ningbo Panic embeds ISO standards into each link of design, production and delivery. Each unit undergoes no less than 50 performance tests to ensure excellent performance output.

Comprehensive test coverage: Including leak detection, noise control, and energy efficiency evaluation, Ningbo Panic ensures the reliability of its products under extreme conditions through laboratory simulation and field tests.

Customer-oriented optimization: Ningbo Panic's quality feedback mechanism collects application data in real time, drives design iterations, and improves product durability.

Question 6: What are the main application scenarios and value of the split lifting column power unit?

Traffic management: used in smart parking systems or roadblock control, Ningbo Panic's units provide fast-response hydraulic power to ensure precise start and stop of the lifting column.

Industrial safety protection: deployed in factories or warehouses, Ningbo Panic's quality testing supports the long-term stability of the unit in high-frequency use scenarios.

Public facility applications: such as squares or venue entrances and exits, Ningbo Panic's separation design simplifies maintenance and reduces operating costs.

Question 7: What added value can you bring by choosing Ningbo Panic's split lifting column power unit?

Performance guarantee commitment: Ningbo Panic's full-process quality testing ensures that the unit is in the best condition when delivered, reducing the customer's subsequent debugging investment.

Technical support and customization: Based on test data, Ningbo Panic provides parameter optimization suggestions to adapt to different load requirements.

Long-term economic efficiency: Ningbo Panic's durable design and high testing standards reduce life cycle maintenance costs and improve return on investment.

English

English 中文简体

中文简体 русский

русский