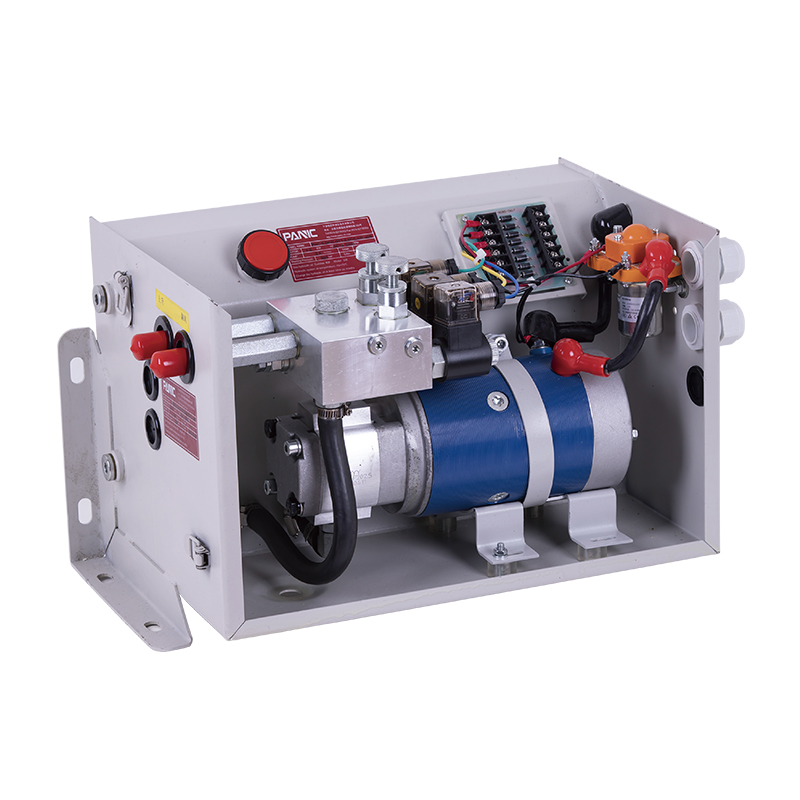

This hydraulic power unit is specially designed for the hydraulic tail plate. The vehicle tail plate hydraulic power unit is a power unit used for the control of the tail plate of the box truck. This series of hydraulic power units realizes the actions of lifting, closing, lowering, and opening the tail plate through the normally closed solenoid valve and solenoid check valve, completes the loading and unloading of goods, and the lowering speed can be adjusted through the throttle valve. 12 and 24V voltages are available.

MAIN FEATURES INCLUDE:

- Solenoid valve control: The hydraulic tailboard power unit accurately controls the lifting, closing, lowering, and opening of the tailboard through a normally closed solenoid valve and a solenoid check valve. The solenoid valve can quickly respond to control signals to ensure the flexibility and accuracy of the tailboard action to meet various needs of cargo loading and unloading.

- Adjustable descent speed: The hydraulic unit is equipped with a throttle valve, and users can adjust the descent speed of the tailboard according to actual needs. This function can effectively avoid vibration or instability caused by too fast descent, ensuring a smoother and safer unloading process.

- Voltage selection: The hydraulic power unit provides two voltage options: 12V and 24V. Users can choose the appropriate voltage configuration according to the vehicle's electrical system to ensure that the power unit can operate stably on different types of trucks.

- Efficient hydraulic control: The system adopts efficient hydraulic control technology to ensure that the tailboard moves accurately and efficiently, and the loading and unloading of goods can be completed quickly. Whether it is lifting or opening and closing the door, it can be carried out smoothly, which greatly improves work efficiency.

- Durable design: The hydraulic tailboard power unit is made of high-quality materials and precision manufacturing, with a long service life and high reliability, suitable for long-term and high-frequency cargo loading and unloading operations.

This hydraulic power unit is suitable for the operation of hydraulic tailboards, and can efficiently and stably support the various functions of the tailboard, helping to complete the loading and unloading tasks of cargo quickly and safely. Whether it is lifting action or door opening and closing control, the system can cooperate accurately to ensure smooth, safe and reliable operation.

SPECIAL NOTES

The power unit is an S3 working system and can not operate continuously. It starts in 10 seconds and stops in 90 seconds.

Before installation, ensure that hydraulic components such as the oil cylinder, oil pipe, and joint are free of impurities.

The viscosity of hydraulic oil shall be 15 - 68st. No. 46 anti-wear hydraulic oil is recommended in summer, and No. 32 low-temperature hydraulic oil is recommended in winter.

After starting the operating system for the first time, check whether the oil in the oil tank is sufficient, generally 2 / 3 of the oil tank.

After the system is used for the first 100 hours, the hydraulic oil shall be replaced, and then the hydraulic oil shall be replaced every 3000 hours.

SCHEMATIC DIAGRAM

SPECIFICATIONS

| Model | Volt | Power | Speed | Displacemet | Pressure | Tank | Solenoid Vavle Volt |

| PNC-1.6-D12-1/1.6-20-10/WB-Y17 | 12VDC | 1.6KW | 2800RPM | 1.6CC/REV | 20MPA | 10L | 12VDC |

| PNC-2.2-D24-1/2.5-20-10/WB-Y17 | 2.2KW | 2600RPM | 2.5CC/REV | 24VDC |

Note: if you need system parameters such as pump, pressure, and motor power with different flow, please contact our salesman.

English

English 中文简体

中文简体 русский

русский