Q: What is the basic definition and core function of a forklift power unit?

A:

The forklift power unit is the central part of the forklift hydraulic system, and is designed to provide a power source for driving the key actions of the forklift (such as lifting, tilting and steering). It efficiently converts mechanical energy into hydraulic energy to ensure that the forklift maintains stability and controllability when carrying heavy objects.

This unit directly affects the operating efficiency, load capacity and operational safety of the forklift. The optimized design can improve the response speed and energy utilization rate and reduce equipment wear.

Ningbo Panic Hydraulic Technology Co., Ltd. relies on the advanced hydraulic technology of Italy's Hydronit and VIS to provide an integrated solution for this unit to ensure zero-failure operation under high-intensity working conditions.

Q: What are the key components of the forklift power unit?

A:

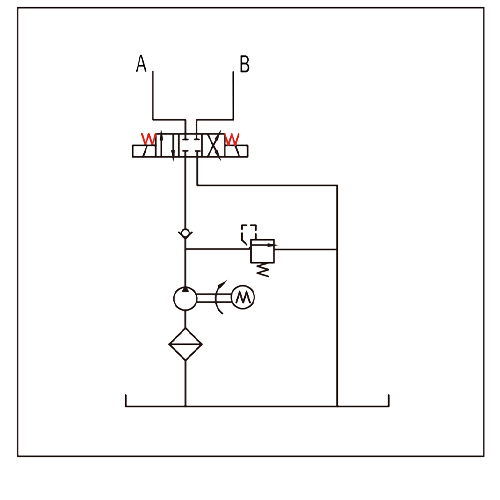

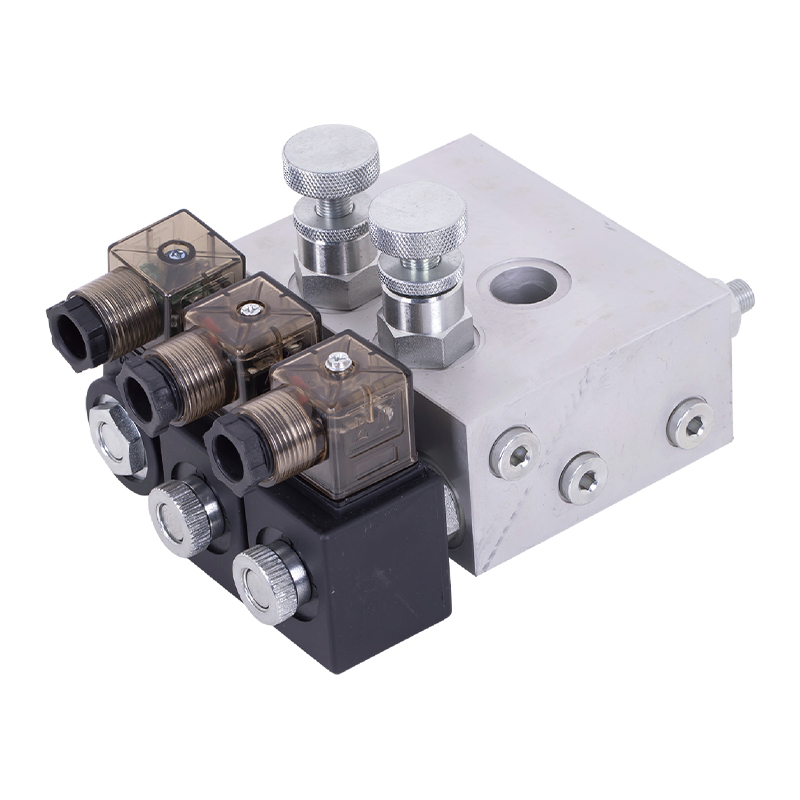

The core components are divided into hydraulic pump, control valve group, hydraulic cylinder, oil tank and filtration system: the hydraulic pump is responsible for energy conversion, converting the input power of the engine or motor into high-pressure oil flow; the control valve group accurately adjusts the oil flow direction and flow rate to achieve fine-tuning control of the fork arm lifting and tilting; the hydraulic cylinder converts hydraulic energy into mechanical movement to drive the fork arm movement; the oil tank and filtration system maintain the cleanliness of the oil to ensure the long-term operation of the system.

The collaborative work of each component determines the overall performance of the unit. For example, the efficient pump design can reduce energy consumption, and the precision valve group improves the operating accuracy.

Ningbo Panic Hydraulic Technology Co., Ltd. uses its patented technology developed in cooperation with Hydronit to produce high-durability pumps and valve groups. These components have been rigorously tested and are suitable for the field of logistics equipment, significantly extending the life of forklifts.

Q: How does the working principle of the forklift power unit reflect efficiency and reliability?

A:

The workflow starts from the power input stage: the engine or electric motor drives the hydraulic pump, and the pump body pressurizes the low-pressure oil and sends it to the control valve; the operator uses the handle command, and the valve group distributes the oil flow direction and pressure in real time, drives the hydraulic cylinder to extend and retract, and finally performs the fork arm action.

High efficiency comes from energy conversion optimization. For example, variable pump technology can automatically adjust the flow according to load requirements to reduce no-load energy consumption; reliability depends on system sealing and anti-pollution design to prevent leakage and component loss.

Ningbo Panic Hydraulic Technology Co., Ltd. integrates VIS's innovative hydraulic technology. The unit design emphasizes low noise and low vibration. It achieves energy saving of more than 30% through intelligent flow control, and adapts to the stringent requirements of forklifts in industrial manufacturing environments.

Q: How does Ningbo Panic Hydraulic Technology Co., Ltd. improve the environmental protection and adaptability of forklift power units?

A:

Based on Hydronit's world-leading hydraulic process, the company develops green solutions: using biodegradable hydraulic oil and high-efficiency filtration system to reduce carbon emissions and environmental pollution during forklift operation; the unit design is compatible with renewable energy sources (such as electric forklifts) to promote energy conservation and environmental protection trends.

In terms of adaptability, the unit can be customized and integrated into various forklift models to ensure seamless compatibility in multiple scenarios such as logistics equipment and warehousing systems; the intelligent diagnostic module is embedded in the system to facilitate remote monitoring and maintenance, reducing downtime.

Ningbo Panic provides comprehensive hydraulic support, from technical consultation to after-market services, covering the entire life cycle of forklift power units; its solutions have been applied to the fields of engineering machinery and industrial manufacturing, helping customers achieve cost savings of more than 30%.

Q: What are the future development trends of forklift power units and Ningbo Panic's contributions?

A:

The development trend focuses on intelligence and modularization: intelligent units integrate sensors and AI-assisted control to achieve adaptive load adjustment and predictive maintenance; modular design simplifies installation and upgrades, and supports the transformation of forklifts to automated logistics.

Ningbo Panic Hydraulic Technology Co., Ltd. promotes industry innovation through continuous research and development: the compact power unit developed in cooperation with VIS is 20% lighter but has higher power density, suitable for narrow aisle forklifts; the company's breakthroughs in energy conservation and environmental protection, such as heat recovery technology, further reduce the total energy consumption of forklifts.

As a leading provider of hydraulic solutions, Ningbo Panic combines forklift power units with the Internet of Things platform to enable customers to improve the overall performance of forklifts and consolidate its position as a technological benchmark in the logistics equipment market.

English

English 中文简体

中文简体 русский

русский