Hydraulic tailboard power unit

Cat:DC series hydraulic power unit

This hydraulic power unit is specially designed for the hydraulic tail plate. The vehicle tail plate hydraulic power unit is a power unit used for the...

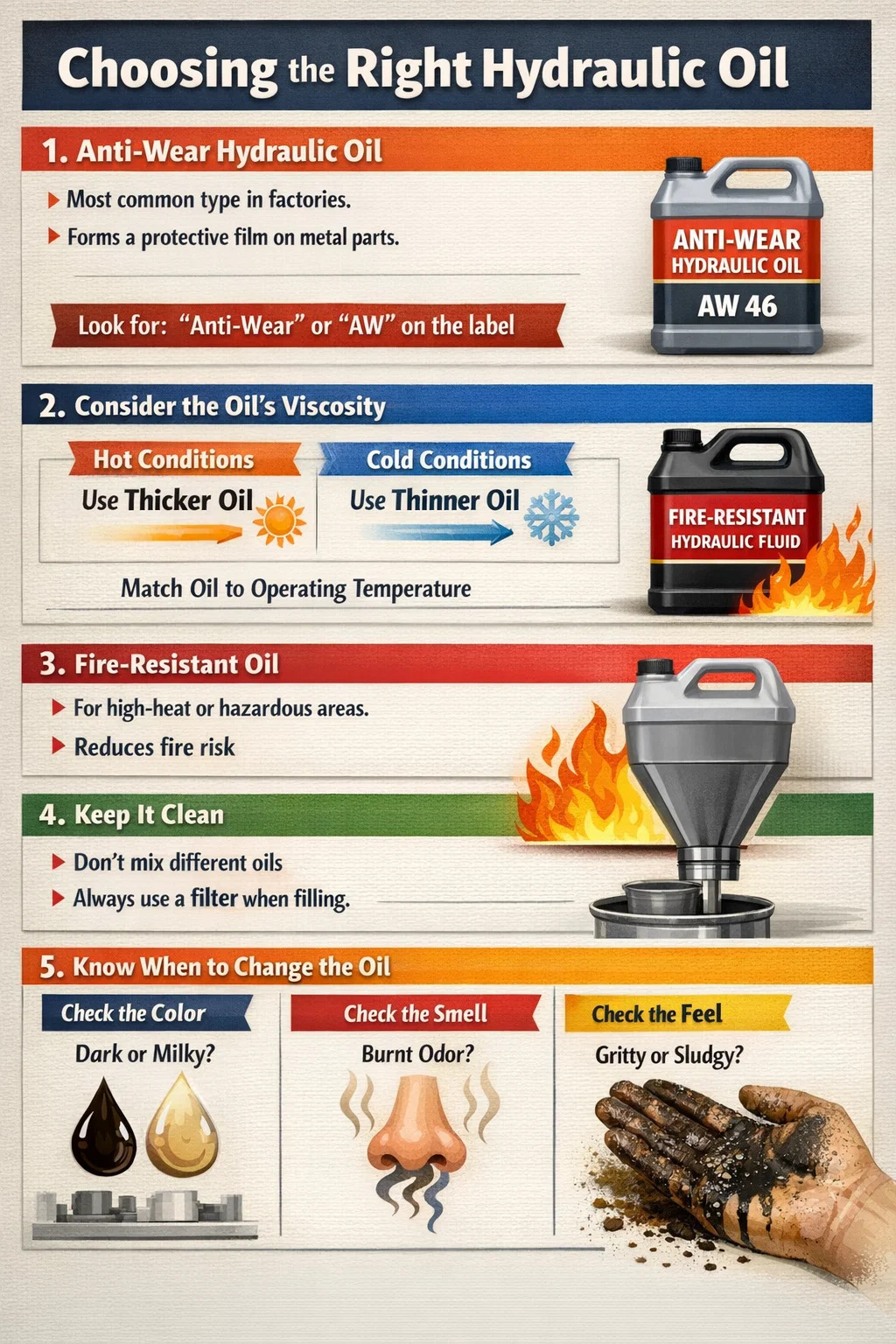

See DetailsAdding oil to a hydraulic power unit is like adding engine oil to a car – you can't just pour in any old oil. Choosing the right oil is crucial for the machine to operate efficiently and reliably.

Hydraulic power units typically use specialized hydraulic oil, but there are several important considerations when choosing the right one:

Content

This is the most common type of oil found in factories.

Its function: It has excellent lubrication properties. Because the pumps and valves inside the hydraulic power unit are precision-machined metal parts, there is significant friction under high pressure. Anti-wear hydraulic oil forms a protective film on the metal surfaces, preventing the parts from wearing down.

Identification: The packaging will usually be marked with terms like "anti-wear" or specific industry codes.

The viscosity of the oil has a significant impact on the system.

Summer or high-temperature environments: If the environment is hot, the oil will become thinner. In this case, you need to choose a slightly "thicker" oil; otherwise, the pressure won't be maintained, and the oil will leak through the gaps like water.

Winter or cold storage environments: If it's cold, the oil will become thicker and more viscous. When the machine starts, the pump will struggle to move the oil, or may even be unable to draw it in. In this case, you need to switch to a "thinner" low-pour-point hydraulic oil to ensure flow even at low temperatures.

In short: Choose the oil based on the operating temperature of your machine.

If your hydraulic power unit is located near a furnace, in a foundry, or in an area with open flames, you absolutely cannot use ordinary mineral oil.

Fire-resistant hydraulic fluid: This type of oil is not easily ignited. If a pipe bursts and oil sprays out, ordinary oil will burn like a fireball, while this special oil significantly reduces the risk of fire.

Hydraulic power units are very "cleanliness-sensitive."

Don't mix oils: Never mix different brands or types of oil. Their chemical additives may react with each other, causing the oil to foam, deteriorate, or produce a sludge-like sediment that clogs the filter.

Even new oil needs filtering: Many people think that newly purchased bottled oil is clean, but this is not the case. Experienced mechanics always use a filter when pouring oil into the fuel tank to prevent metal shavings or dust from the bottom of the container from entering the system.

Simply adding oil without changing it is not enough. You can observe the following points:

Check the color: Clean oil is golden and transparent. If it turns black, it means it has burned or is dirty; if it turns white like milk, it means water has entered the system.

Check the smell: If you smell a burnt odor, it means the oil has deteriorated due to high temperatures.

Check the feel: Normal oil is slippery. If it feels gritty or sandy, you must replace the oil and clean the fuel tank immediately.