Portable stacker power unit

Cat:DC series hydraulic power unit

This portable stacker hydraulic power unit is designed for portable stackers and integrates a high-pressure gear pump, a permanent magnet DC motor, a ...

See DetailsHydraulic power units are indeed noisy, and in factory workshops, they are often one of the main sources of noise.

However, this sound is not constant. Its loudness depends on its design, installation method, and operating condition. Here is a detailed explanation of the noise issues with hydraulic power units:

Content

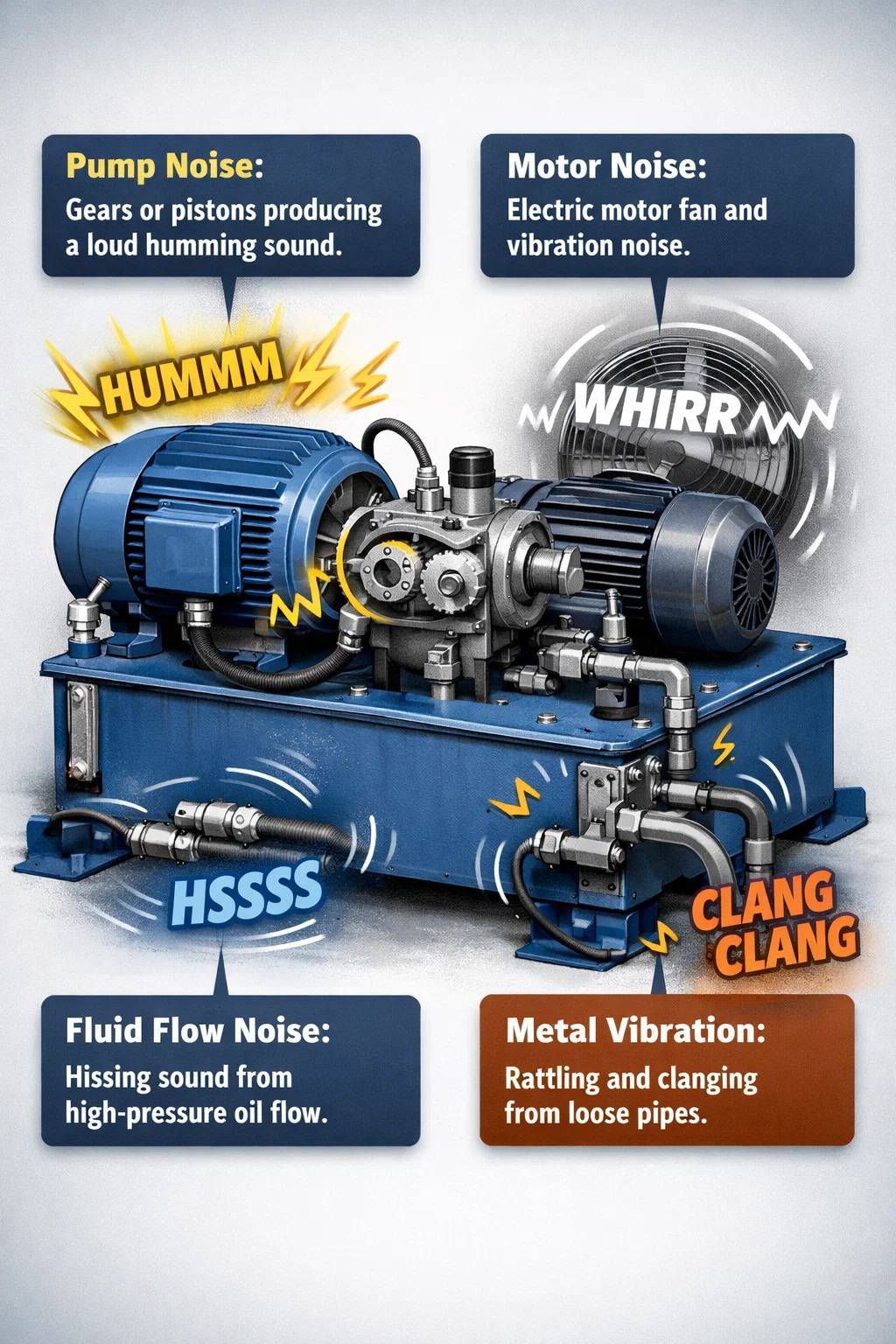

Hydraulic power units produce sound mainly because several core components are working simultaneously:

This is the main source of sound. The gears or pistons inside the pump produce a regular humming sound as they rotate and reciprocate at high speed.

The electric motor that drives the pump itself produces fan cooling noise and electromagnetic vibration noise.

High-pressure hydraulic oil flows rapidly through narrow pipes and valves, producing a "hissing" sound, especially when the pressure changes suddenly.

If the pipes are not properly secured, the vibration during machine operation can cause resonance in the surrounding metal casing or brackets, producing a clanging sound.

If the sound of the hydraulic power unit suddenly becomes louder or harsher, it usually indicates a problem:

This is the most unpleasant sound, sounding like pouring gravel into the pump. This is because the oil level in the tank is too low or there is an air leak in the inlet pipe, causing the pump to ingest air.

Just like a person with a stuffy nose, a dirty filter element makes it difficult for the pump to draw oil, producing a muffled struggling sound.

If the coupling between the motor and the pump is damaged or misaligned, it will produce a sharp metal friction sound.

While it cannot be completely silent, there are many ways in manufacturing to make hydraulic power units quieter:

Add a sound insulation cover to the entire unit, or place anti-vibration rubber pads under the oil tank and motor.

Using high-pressure flexible hoses instead of rigid steel pipes can effectively absorb vibrations.

Using a variable-frequency motor allows the motor to rotate slower when less power is needed, naturally reducing noise.

Some designs submerge the pump directly in the hydraulic fluid of the oil tank, using the hydraulic oil to dampen noise.

Experienced technicians can usually determine the health of hydraulic power units simply by listening to the sound, without needing to look at the pressure gauge:

Indicates everything is normal.

May indicate the pressure setting is too high or the oil is too viscous.

May indicate wear or detachment of internal parts.