Portable stacker power unit

Cat:DC series hydraulic power unit

This portable stacker hydraulic power unit is designed for portable stackers and integrates a high-pressure gear pump, a permanent magnet DC motor, a ...

See DetailsContent

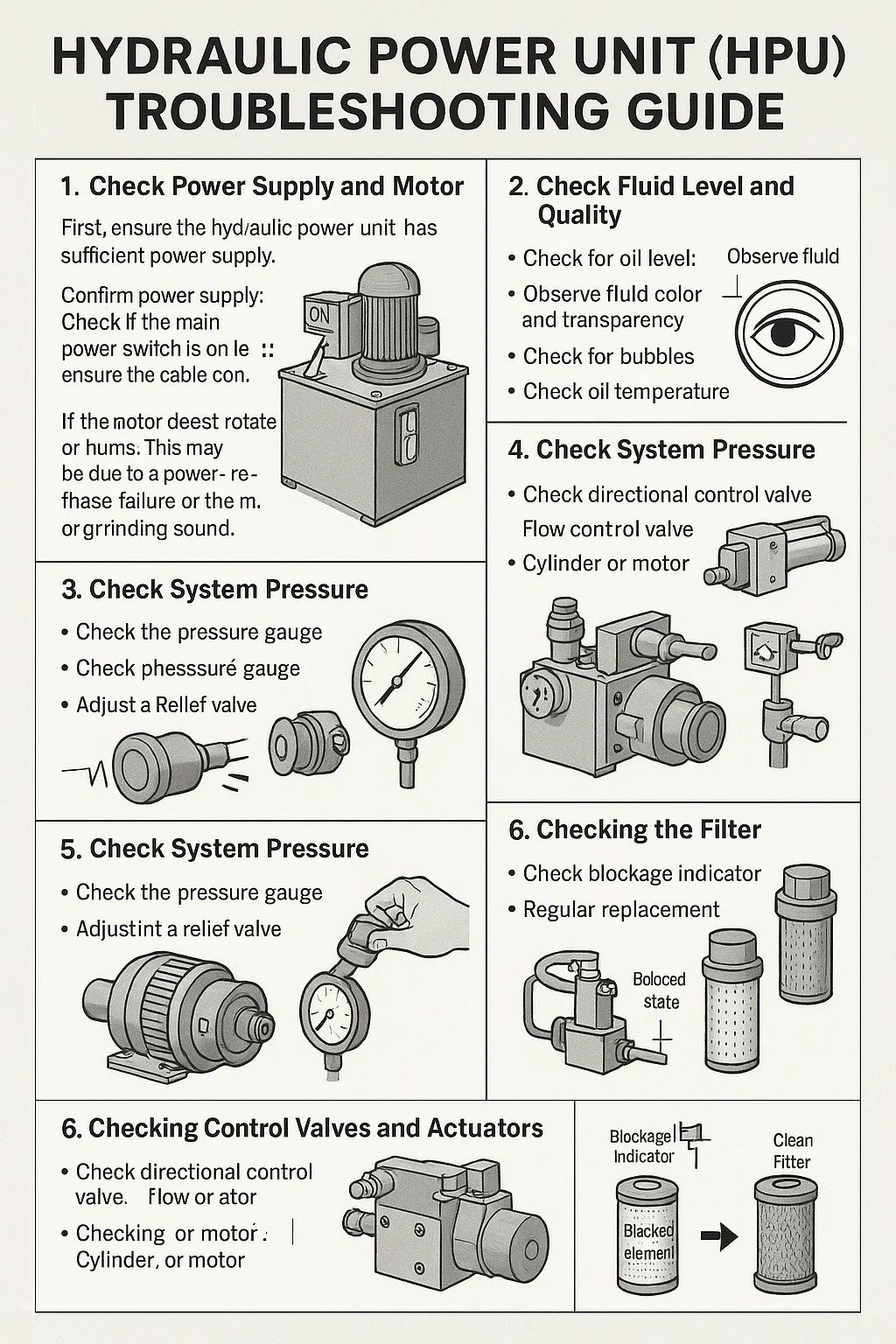

When your hydraulic system experiences problems, you can usually start troubleshooting by checking the following key points:

First, ensure the hydraulic power unit has sufficient power supply and can start normally.

Confirm power supply: Check if the main power switch is on and ensure the cable connections are secure.

Listen to the motor sound: Listen to the motor sound when it starts to see if it is normal.

If the motor does not rotate or hums: This may be due to a power phase failure, insufficient voltage, or the motor overload protection tripping. Check the fuses and circuit breakers.

If the motor sound is sharp or there is a grinding sound: The bearing may be damaged and needs to be stopped and repaired.

Hydraulic fluid is the "blood" of the hydraulic power unit (HPU). The condition of the fluid is crucial to system performance.

Check the oil level: Check the level gauge on the oil tank. A low oil level can cause the pump to suck in air, generating noise and damaging the hydraulic pump.

Check the fluid:

Observe the color and transparency: Normal hydraulic fluid should be clean and transparent. If the fluid is dark, cloudy, or milky (possibly due to water ingress), it needs to be replaced.

Check for bubbles: A large number of bubbles indicates that the system has ingested air.

Check the oil temperature: High oil temperature (overheating) will accelerate fluid degradation and damage seals.

The hydraulic pump is the core component that generates pressure in the hydraulic power unit.

Check for noise:

Abnormal noise (screeching, clicking): This may be due to a blocked suction line, air ingress, incorrect fluid viscosity, or internal wear of the pump itself.

Check the suction line: Ensure the filter is not clogged and there are no leaks in the pipeline.

Check the pressure: If the system cannot build or maintain the required pressure, the pump may be severely worn, or the relief valve (safety valve) is improperly set or damaged.

Is the system pressure reaching the required level and remaining stable during operation?

Check the pressure gauge: Observe whether the pressure gauge reading is within the normal operating range. Adjusting the Relief Valve: The relief valve (the safety valve in the system) is used to set the maximum working pressure of the system. If the pressure is too low, try fine-tuning the relief valve setting (but do not over-adjust). If the adjustment is ineffective, the valve spool may be stuck or the spring may be damaged.

Control valves are responsible for controlling the direction and flow rate of the hydraulic fluid, and actuators (cylinders or motors) are responsible for performing the actions.

Check the directional control valve: Ensure that the valve spool switches smoothly to the correct position. If the actuator (such as a cylinder) is slow to move or does not move at all, the valve spool may be stuck or the solenoid coil may be faulty.

Check the flow control valve: If the actuator's movement speed is abnormal (too fast or too slow), check if the flow control valve is set correctly or is blocked.

Check the cylinder or motor:

Cylinder "creeping" or position drift: This may be due to damaged internal seals in the cylinder, or a leak in the control valve.

The filter is used to remove impurities from the hydraulic fluid and protect system components.

Check the blockage indicator: Many filters have a blockage indicator. If the indicator shows a blockage, the filter element needs to be cleaned or replaced immediately.

Regular replacement: If the filter element is not replaced for a long time, it will affect oil suction, increase the burden on the pump, and may even lead to a lack of oil in the system.