Mobile lifting platform power unit

Cat:DC series hydraulic power unit

This hydraulic power unit is specially designed for a mobile hydraulic lifting table, which is integrated with a high-pressure gear pump. permanent ma...

See DetailsContent

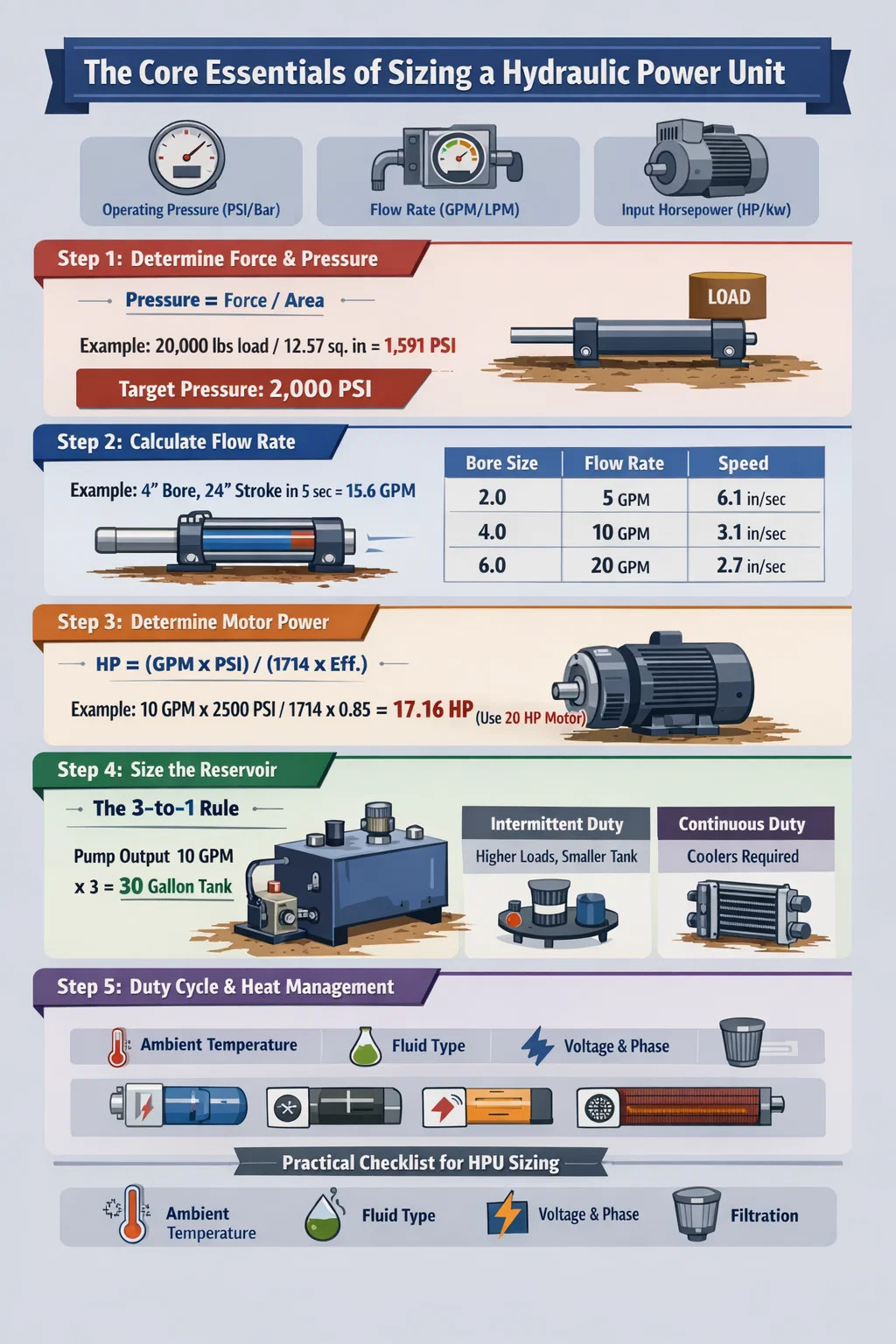

To properly size a hydraulic power unit (HPU), you must define the mechanical output requirements of your application first. The process is not about picking a generic motor; it is a precise sequence of determining the required force, the speed of operation, and the resulting flow and pressure demands. The fundamental answer lies in three primary calculations: Operating Pressure (PSI/Bar), Flow Rate (GPM/LPM), and Input Horsepower (HP/kW).

A mismatched hydraulic power unit leads to either extreme energy waste and heat generation (if oversized) or failure to complete the mechanical task (if undersized). The goal is to balance the performance of the hydraulic pump, the capacity of the reservoir, and the strength of the electric motor or engine.

The pressure generated by the hydraulic power unit is a direct result of the load resistance. You do not choose a pressure arbitrarily; you calculate it based on the surface area of your actuator (cylinder or motor).

To calculate the required pressure, use the formula: Pressure = Force / Area. For example, if you need a hydraulic cylinder to push a 20,000-pound load and you are using a cylinder with a 4-inch bore (area = 12.57 sq. in.), the required pressure is approximately 1,591 PSI. You should typically add a 10-20% safety margin to account for friction and line losses, meaning your hydraulic power unit should be capable of at least 2,000 PSI.

Flow rate, measured in Gallons Per Minute (GPM) or Liters Per Minute (LPM), dictates how fast your machine moves. The hydraulic power unit must move a specific volume of oil into the cylinder to extend it over a certain time.

Example: If that same 4-inch bore cylinder has a 24-inch stroke and must extend in 5 seconds, you must first calculate the volume. The volume is roughly 1.3 gallons. To move 1.3 gallons in 5 seconds, the hydraulic power unit needs a pump capable of roughly 15.6 GPM.

| Bore Diameter (Inches) | Flow Rate (GPM) | Cylinder Speed (Inches/Sec) |

|---|---|---|

| 2.0 | 5 | 6.1 |

| 4.0 | 10 | 3.1 |

| 6.0 | 20 | 2.7 |

Once you have determined the pressure and flow, you can calculate the required input power for the hydraulic power unit. The standard rule of thumb is the "1 HP for 1 GPM at 1500 PSI" rule, but a more exact calculation is necessary for efficiency.

Use the formula: HP = (GPM × PSI) / (1714 × Efficiency). Most hydraulic pumps have an efficiency rating between 0.85 and 0.90. If your system requires 10 GPM at 2,500 PSI, the calculation would be (10 × 2500) / (1714 × 0.85), resulting in a requirement of roughly 17.16 HP. In this case, you would select a standard 20 HP motor for your hydraulic power unit.

The reservoir is a critical component of the hydraulic power unit that is often overlooked. It must be large enough to allow for thermal expansion, cooling, and the settling of contaminants.

In standard industrial applications, the reservoir should hold three times the pump's GPM output. If your hydraulic power unit utilizes a 10 GPM pump, the tank should ideally hold 30 gallons of fluid. This ensures that the oil spends enough time "at rest" to dissipate heat before being sucked back into the pump.

However, if space is limited or the duty cycle is intermittent, you might use a 1-to-1 or 2-to-1 ratio, provided you add an oil cooler to manage the temperature. Excessive heat is the primary killer of hydraulic seals and fluid longevity.

The duty cycle of your hydraulic power unit dramatically impacts its design. A unit that runs for 10 seconds every hour is sized differently than one that runs continuously on a factory floor.

Before finalizing the purchase or build of a hydraulic power unit, verify the following environmental and mechanical factors:

By strictly following these calculation steps, you ensure that your hydraulic power unit provides reliable, efficient service for its entire lifespan without unnecessary energy costs or mechanical failures.