Portable stacker power unit

Cat:DC series hydraulic power unit

This portable stacker hydraulic power unit is designed for portable stackers and integrates a high-pressure gear pump, a permanent magnet DC motor, a ...

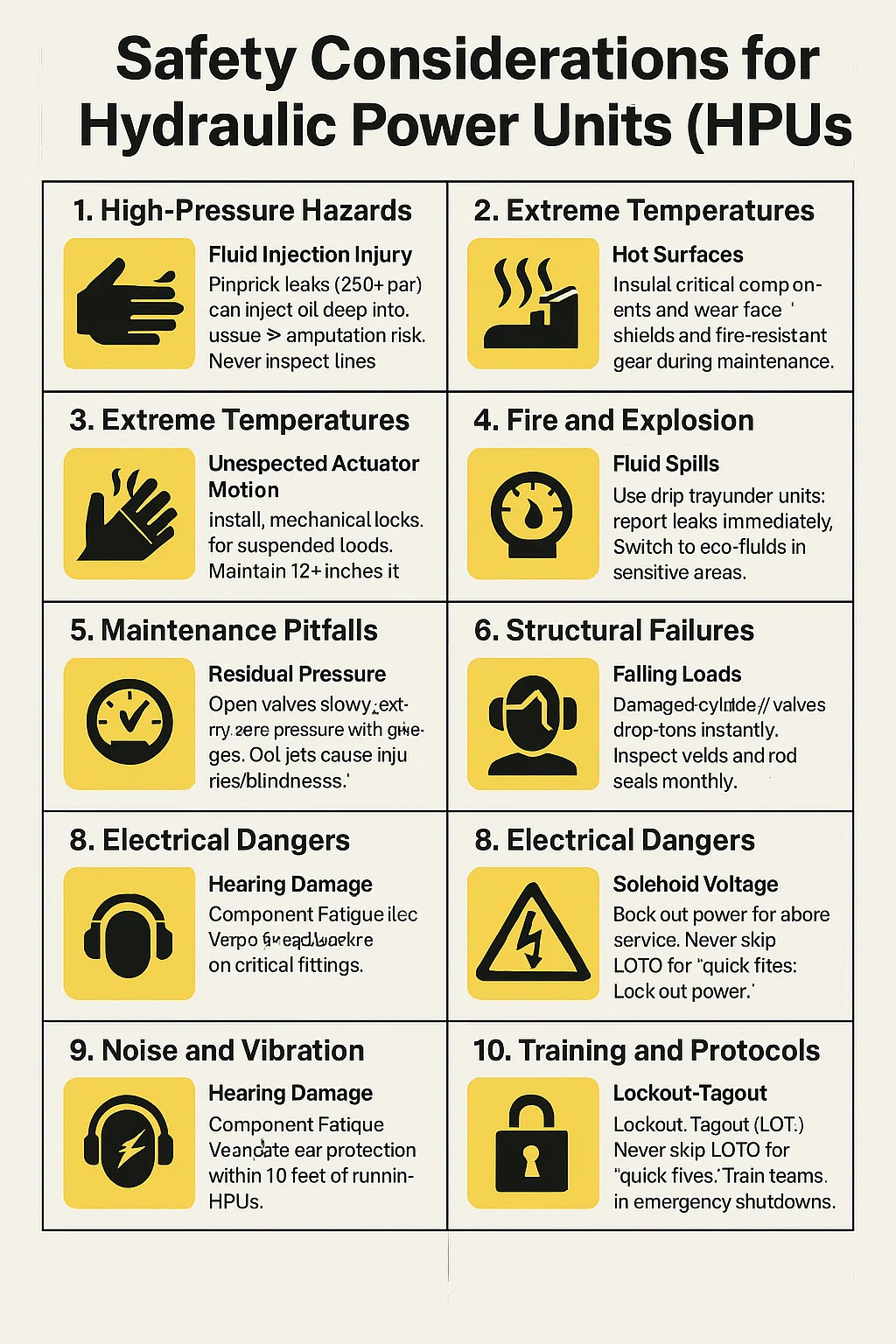

See DetailsSafety Considerations for Hydraulic Power Units (HPUs)

Content

Fluid Injection Injury: Pinprick leaks (250+ bar) can inject oil deep into tissue → amputation risk. Never inspect lines with bare hands.

Hose/Fitting Bursts: Worn hoses or loose fittings explode under pressure → shrapnel risk. Use safety cages for high-pressure test zones.

Hot Surfaces: Reservoirs, valves, and pipes reach 80°C+ → contact causes third-degree burns. Insulate critical components.

Fluid Burns: Pressurized leaks vaporize into scalding mist. Wear face shields and fire-resistant gear during maintenance.

Unexpected Actuator Motion: Electrical/valve failures cause cylinders/motors to move uncontrollably. Install mechanical locks for suspended loads.

Pinch Points: Cylinder rods and linkages crush limbs. Maintain 12+ inches clearance from moving parts during operation.

Flammable Fluids: Mineral oil ignites at 250°C. Avoid welding near leaks; keep fire extinguishers (Class B) accessible.

Hot Surfaces Ignite Leaks: Hydraulic spray hitting hot exhausts/engines → flash fires. Route hoses away from heat sources.

Fluid Spills: 1 liter of oil contaminates 1 million liters of water. Use drip trays under units; report leaks immediately.

Soil Toxicity: Non-biodegradable fluids poison ecosystems. Switch to eco-fluids (e.g., HETG) in sensitive areas.

Residual Pressure: Systems hold pressure for hours after shutdown. Open valves slowly; verify zero pressure with gauges.

Controlled Bleed-Down: Never disconnect lines before depressurizing → oil jets cause injuries/blindness.

Falling Loads: Damaged cylinders/valves drop tons instantly. Inspect welds and rod seals monthly.

Tank Collapse: Clogged breathers create vacuum → implodes reservoirs. Clean breathers quarterly.

Solenoid Voltage: 24V DC solenoids ≠ low risk. Wet environments induce stray currents → shocks. Lock out power before service.

Grounding Failures: Static sparks ignite oil mist. Bond all components to a common ground point.

Hearing Damage: Gear pumps emit 85+ dB. Mandate ear protection within 10 feet of running HPUs.

Component Fatigue: Vibration loosens bolts → leaks. Use thread-locker on critical fittings.

Lockout-Tagout (LOTO): Isolate energy sources during repairs. Never skip LOTO for "quick fixes."

Containment Kits: Keep spill absorbents and gloves near HPUs. Train teams in emergency shutdowns.