Mini Pallet Truck Hydraulic Power Unit

Cat:DC series hydraulic power unit

This hydraulic power unit is specially designed for all electric pallet truck.It consists of high voltage gear pump,permanent magnet DC motor and cent...

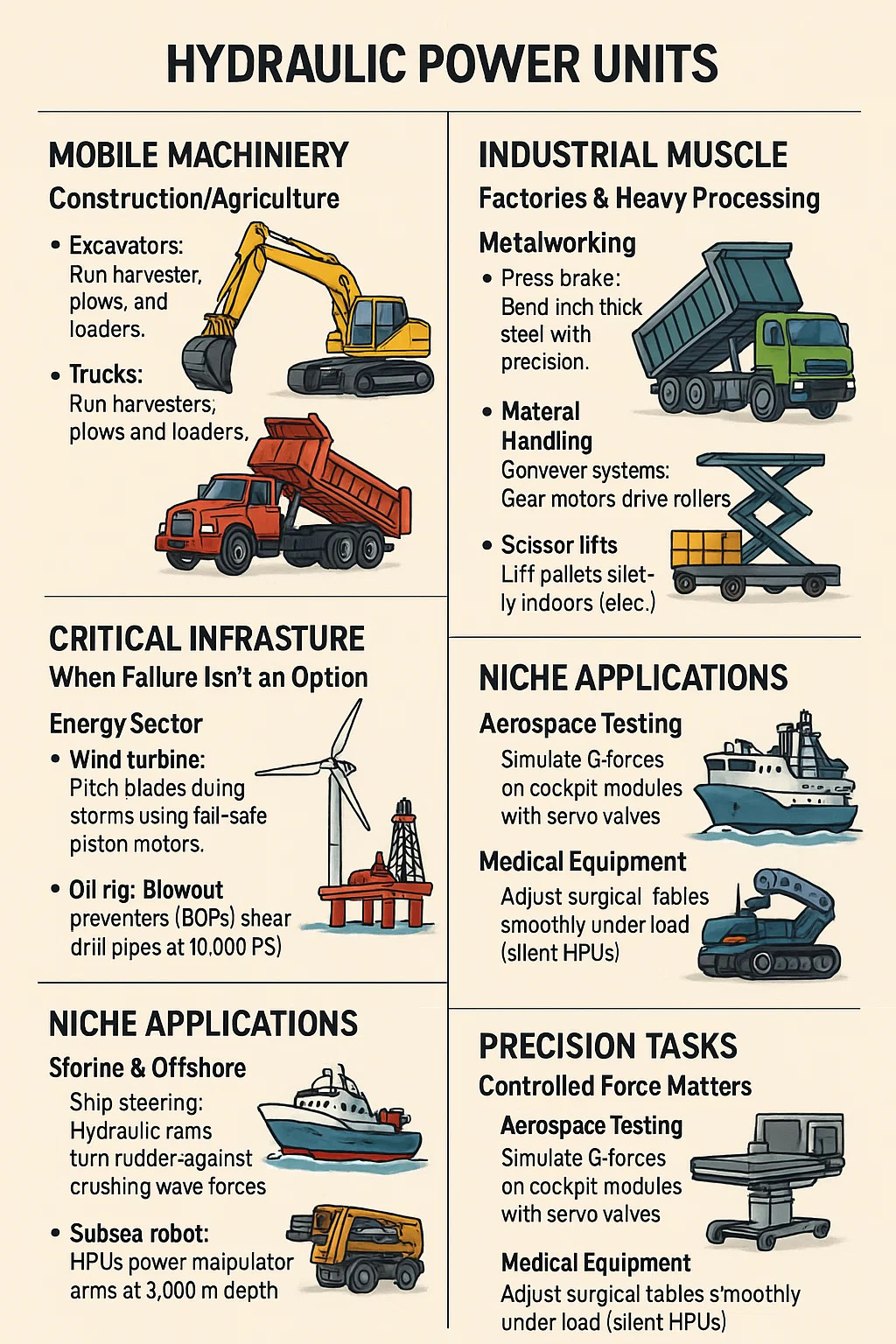

See DetailsHere's a no-nonsense breakdown of where hydraulic power units (HPUs) dominate in the real world, based on their brute-force capabilities and environmental toughness:

Content

Excavators: HPUs power boom arms, bucket curl, and track drives. Hydraulics outmuscle electrics in mud/debris.

Tractors: Run harvesters, plows, and loaders. Engine-driven HPUs laugh at dust storms.

Dump trucks: Lift 50-ton beds reliably. No gearboxes to strip.

Tow trucks: Winch wrecked vehicles with controlled torque.

Press brakes: Bend inch-thick steel with precision. Hydraulic control prevents springback.

Injection molding: Clamp molds under 3,000 tons of force. Smooth pressure curves prevent part flaws.

Conveyor systems: Gear motors drive rollers in wet/dirty warehouses.

Scissor lifts: Lift pallets silently indoors (electric HPUs).

Wind turbines: Pitch blades during storms using fail-safe piston motors.

Oil rigs: Blowout preventers (BOPs) shear drill pipes at 10,000 PSI.

Aircraft: Lower landing gear if engines fail (no electricity needed).

Bridge lifts: Raise drawbridges with synchronized cylinders.

Ship steering: Hydraulic rams turn rudders against crushing wave forces.

Subsea robots: HPUs power manipulator arms at 3,000m depth.

Longwall shearers: Cut coal seams with explosion-proof HPUs.

Roof bolters: Secure tunnel ceilings in methane-rich air.

Simulate G-forces on cockpit modules with servo valves.

Adjust surgical tables smoothly under load (silent HPUs).