Hydraulic tailboard power unit

Cat:DC series hydraulic power unit

This hydraulic power unit is specially designed for the hydraulic tail plate. The vehicle tail plate hydraulic power unit is a power unit used for the...

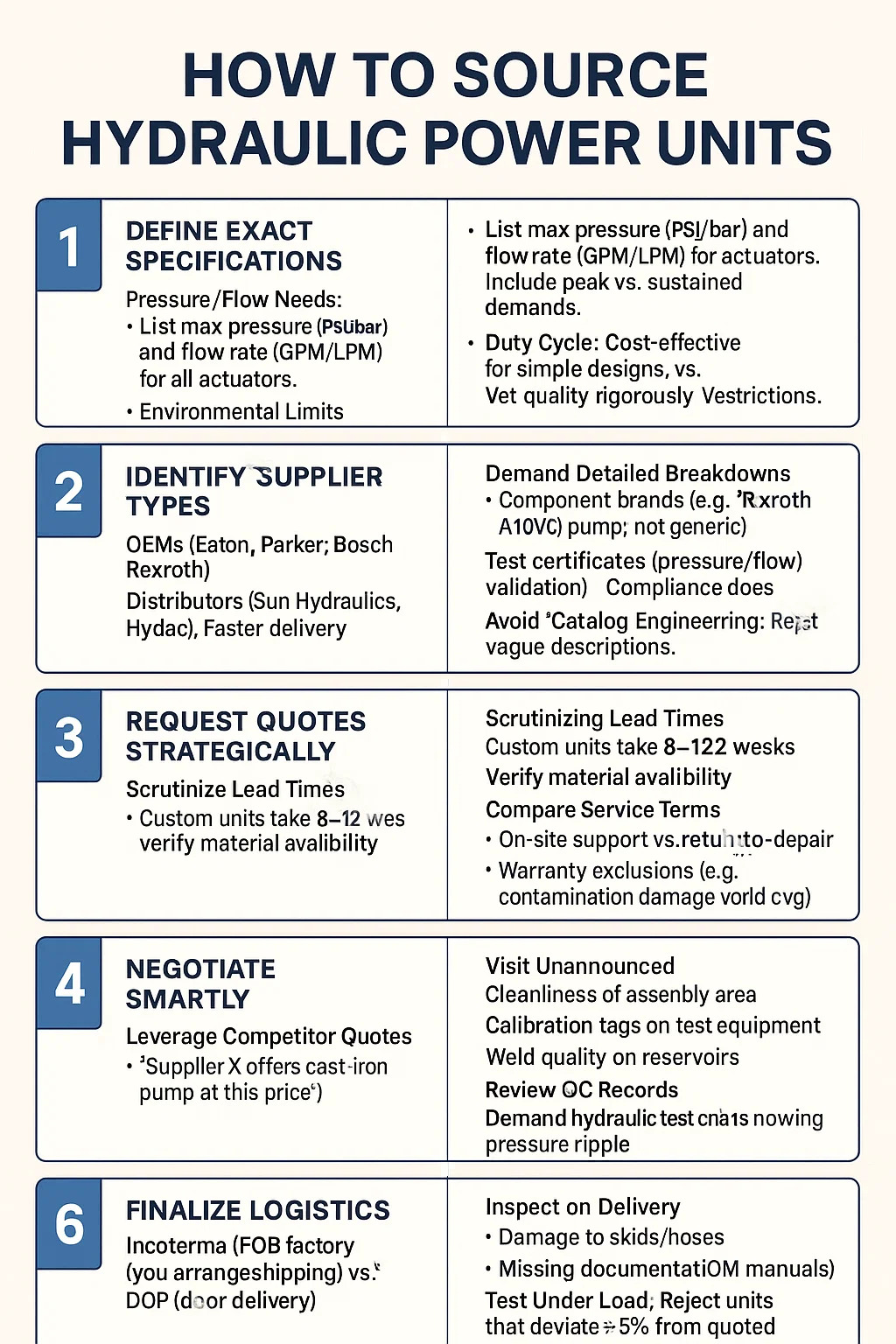

See DetailsHere's a step-by-step guide to sourcing hydraulic power units, distilled from industry experience:

1. Define Exact Specifications

Pressure/Flow Needs: List max pressure (PSI/bar) and flow rate (GPM/LPM) for all actuators. Include peak vs. sustained demands.

Duty Cycle: Specify operating hours (e.g., 24/7 continuous vs. 30-min bursts).

Environmental Limits: Note temperature extremes, dust, water exposure, noise restrictions.

2. Identify Supplier Types

OEMs (Eaton, Parker, Bosch Rexroth): For custom-engineered units with warranties.

Distributors (Sun Hydraulics, Hydac): For modified standard units; faster delivery.

Local Fabricators: Cost-effective for simple designs; vet quality rigorously.

3. Request Quotes Strategically

Demand Detailed Breakdowns:

Component brands (e.g., "R Component brands (e.g., "Rexroth A10VO pump, not generic")

Test certificates (pressure/flow validation)

Compliance docs (CE, ISO 4413)

Avoid "Catalog Engineering": Reject vague descriptions like "10 GPM unit."

4. Evaluate Proposals

Scrutinize Lead Times: Custom units take 8–12 weeks; verify material availability.

Compare Service Terms:

On-site support vs. return-to-depot repairs

Warranty exclusions (e.g., contamination damage voiding coverage)

Demand Failure Data: Ask for MTBF (mean time between failures) for pumps/valves.

5. Negotiate Smartly

Leverage Competitor Quotes: "Supplier X offers cast-iron pump at this price."

Push for Value Adds:

Free startup supervision

Extended filter warranties

Spare valve coils included

6. Audit Manufacturing (For Custom Units)

Visit Unannounced: Check:

Cleanliness of assembly area

Calibration tags on test equipment

Weld quality on reservoirs

Review QC Records: Demand hydraulic test charts showing pressure ripple.

7. Finalize Logistics

Incoterms Matter: FOB factory (you arrange shipping) vs. DDP (door delivery).

Pre-Install Checks:

Verify fluid compatibility

Confirm voltage/fuel type matches site

Check flange/port standards (SAE, DIN)

8. Post-Purchase Actions

Inspect on Delivery:

Damage to skids/hoses

Missing documentation (IOM manuals)

Test Under Load: Reject units that deviate >5% from quoted performance.