Hydraulic power unit of full electric stacker

Cat:DC series hydraulic power unit

This hydraulic power unit of full electric stacker is specially designed for full electric stacker. It is integrated by a high-pressure gear pump, a D...

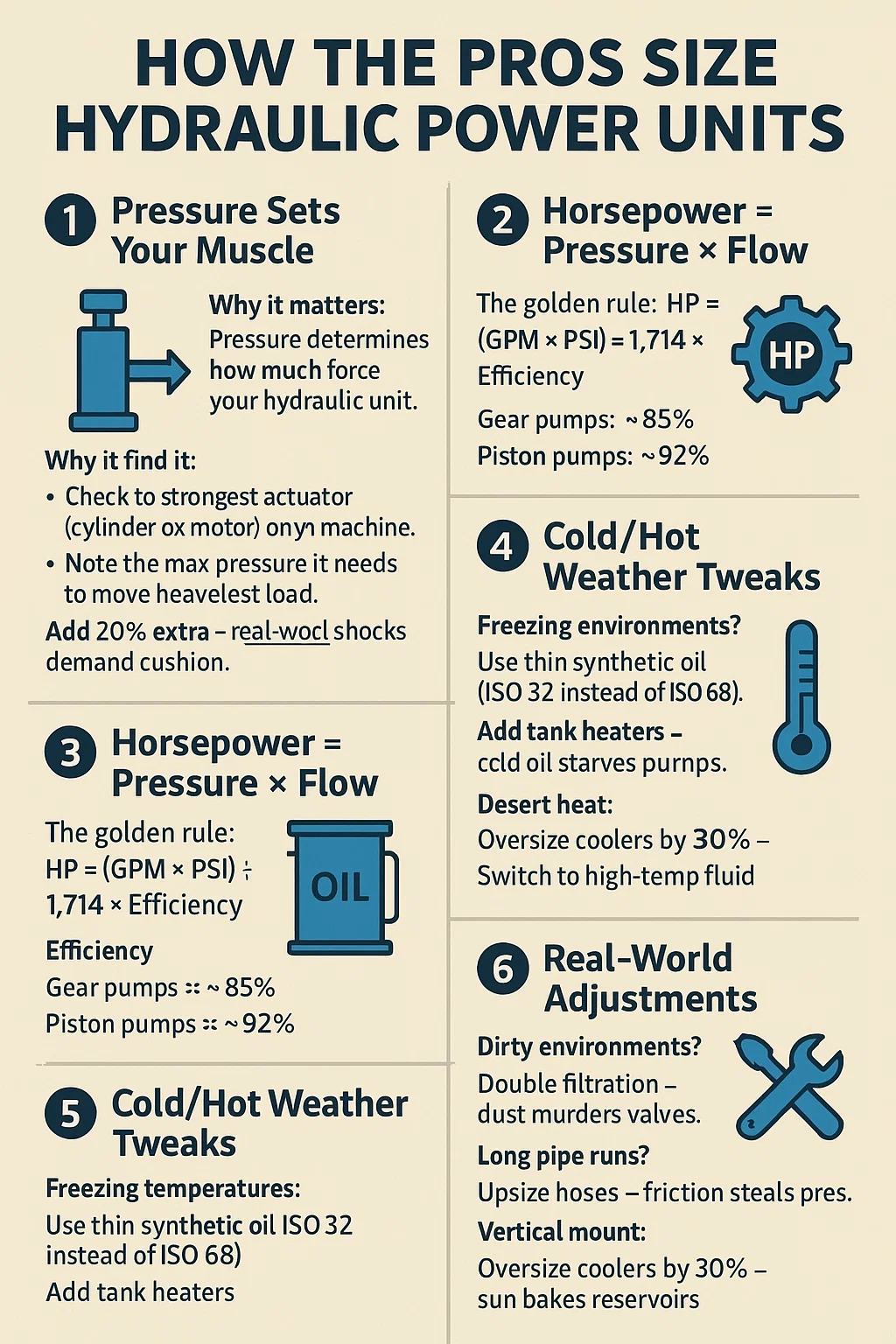

See DetailsHere's how seasoned pros size hydraulic power units:

Content

Why it matters: Pressure determines how much force your hydraulic power unit can push.

How to find it:

Check the strongest actuator (cylinder or motor) on your machine.

Note the max pressure it needs to move the heaviest load.

Add 20% extra – real-world shocks demand cushion.

Example: Your log splitter cylinder needs 2,000 PSI? Aim for 2,400 PSI-capable components.

Why it matters: Flow (GPM or LPM) decides how fast actuators move.

Calculate it:

For cylinders: (Cylinder bore area × Stroke length) ÷ Time to complete stroke

For motors: Motor size × RPM needed

Add 'em up: If multiple actuators run together, sum their flows.

Tip: Need speed? Prioritize flow. Need brute force? Prioritize pressure.

The golden rule: HP = (GPM × PSI) ÷ 1,714 × Efficiency

Efficiency realities:

Gear pumps: ~85%

Piston pumps: ~92%

Always oversize: Buy 20% more HP than calculated – pumps hate being maxed out.

Light use (occasional lifts): Tank holds 3× pump flow rate.

Heavy cycling (continuous operation): 5× flow rate minimum.

Hot climates? Add 20% volume – heat needs space to dissipate.

Freezing temps:

Use thin synthetic oil (ISO 32 instead of ISO 68).

Add tank heaters – cold oil starves pumps.

Desert heat:

Oversize coolers by 30% – sun bakes reservoirs.

Switch to high-temp fluid – standard oil cooks into sludge.

Dirty environments: Double filtration – dust murders valves.

Long pipe runs: Upsize hoses – friction steals pressure.

Vertical mount: Ensure pump sits below oil level – gravity feeds better than suction lifts.